32

iQUBE

Installation Manual

calibration.

NOTE:

Cal-Match calibration can

be canceled by pressing the

CLE

A

R

key.

6. Ensure scale is empty, then use the

up

and

down

keys to select

Corner Cal-Match

(see

Figure 5-2

)

or

S

ection Cal-Match

. Press

enter

.

The

iQUBE

calculates the zero reference

point.

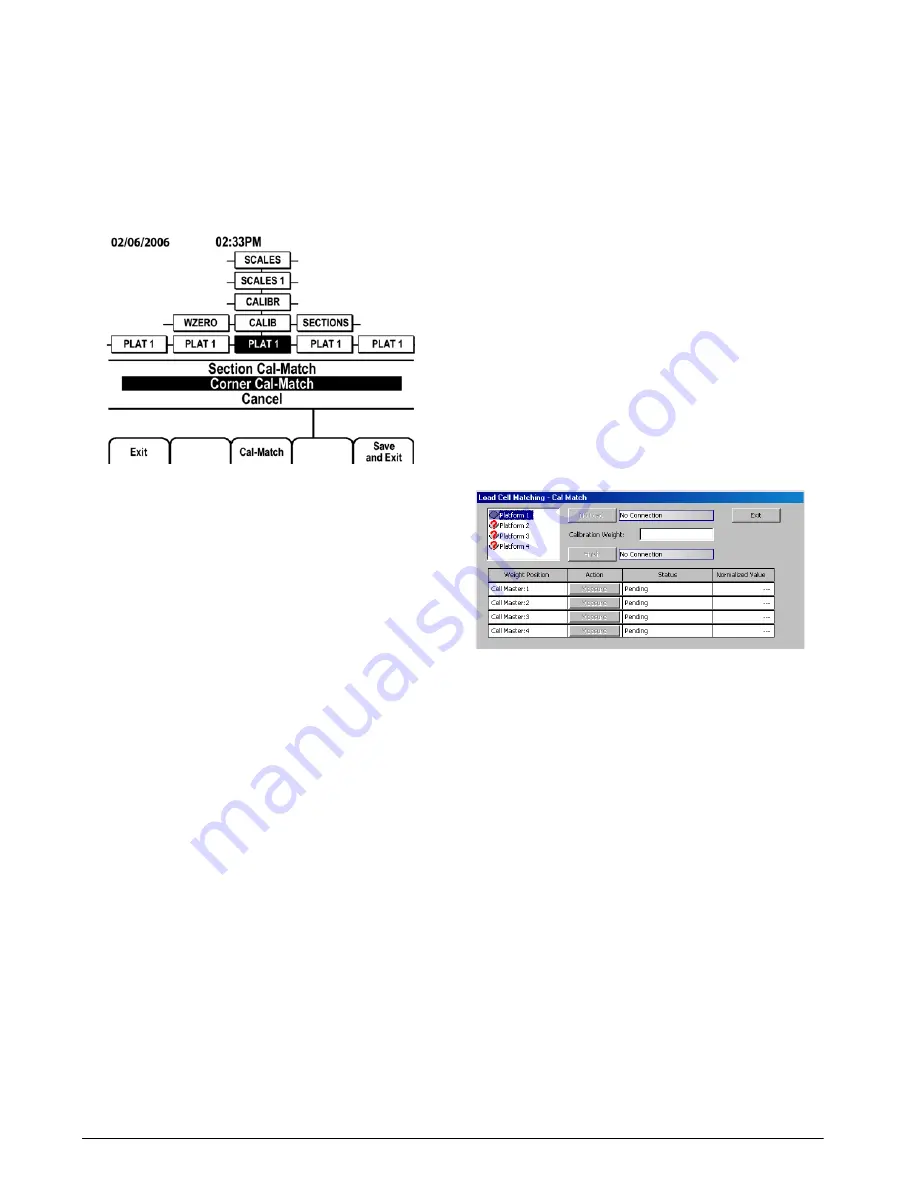

Figure 5-2.

920i

Cal-Match Selection

7. The display now prompts

Cal-Match Point 1

.

Place a test weight over the cell or section to

be tested, then press

enter

.

NOTE:

It is not

n e c e s s a r y t o m e a s u r e t h e c e l l s i n a n y

particular order.

8. Once the

iQUBE

has read the cell, the

920i

display will show

Cal-Match Point 2

. Move the

test weight to the next cell or section and

press

enter

. Repeat until all cells have been

measured.

9. When the last cell has been measured, the

iQUBE

automatically sets the load cell trim

factors. The

920i

display shows

Calibration

Complete

.

10. Press

up

to return to the SCALES menu, or

press the

S

ave and Exit

softkey to exit setup

mode.

NOTE:

Cal-Match calibration can be performed using

a vehicle as the test weight, but a smaller footprint and

heavier weight value will yield better results.

Mechanical characteristics of the scale may prevent

Cal-Match from automatically computing load cell

trim factors.

5.1.3

Manual Trim Factor Adjustment (Tweaking)

Section or corner trim factors can be manually

tweaked. When using the

iQUBE

with a

920i

indicator,

use the

up

or

down

navigation key to select the section

or corner to be adjusted, then use the

Tweak –

or

Tweak

+

softkey to adjust the value. The displayed weight for

the scale system is shown at the bottom of the weight

column.

Tweaking can be performed following a Cal-Match

calibration or when replacing a load cell.

5.1.4

Final Calibration

The span and linear calibration displays provide a

Calibration

softkey to perform a traditional calibration

for the selected point. Enter the weight value under

WVAL, then press the

Calibration

softkey under

WSPAN for each platform. Continue under WLIN for

systems using linear calibration.

Trim factors displayed for sections or corners can be

manually tweaked up or down. The cell with the

lowest output is given a trim factor of 1.0000.

5.2

Revolution III Calibration

Cal-Match Calibration

With the

iQUBE

connected to a PC running the

Revolution III

program, do the following:

1. From the Interactive menu, select

Cal-Match

Load Cell Matching…

(see Figure 5-3).

Figure 5-3. Cal-Match Load Cell Matching Display

2. Remove all weight from the scale platform.

Click on

No Load

. The word

Transmitting

is

displayed while the no-load values are

calculated. This process can last up to 45

seconds.

3. Enter the test weight value in the

Calibration

Weight

field. You are now ready to measure

the load cell outputs using the Cal-Match

procedure.

4. Place the test weight over the cell to be

measured. It is not necessary to measure the

cells in any particular order.

5. Click the first

Measure

box. As each cell is

completed the next cell becomes available for

measurement.

6. Repeat steps 4 and 5 until all cells have been

measured.

7. Click

Finish

. Cal-Match automatically

calculates the load cell trim factors. These

normalized sensitivity values are displayed

for each cell in the platform.

8. Click

Exit

.