3

Tighten feed screw.

RC30S in use

with FPV20 vise.

Saddle held in

place by chain.

Saddle holds

ratchet handle.

CAUTION:Always wear

proper eye protection

when using this or any

hand tool.

hammer and chisel or coarse file may also be used. This will help

save cutter wheels and cutting time; and helps to square the cutter

on the pipe to ensure tracking.

HELPFUL HINTS:

On large diameter pipe, it may be desirable

to alternate two workers pulling on the handle. Failure to maintain

maximum preassure only results in wasted time. While cast and

ductile iron pipe will fracture along the cut line after penetrating part

way, continue feeding the wheels in to make sure the cut is com-

pleted. Ductile iron tends to work harden. Continuous feeding and

maximum pressure helps prevent this. If some ductile iron needs to

be cut all the way through, consider using cutter wheels for steel, as

they will cut much faster. The steel cutter wheels will not last as long

as cutter wheels for ductile, and may be only effective on less hard

ductile iron.

OPERATING INSTRUCTIONS for RC30,

RC36, and RC42 Rotary™ Cutters

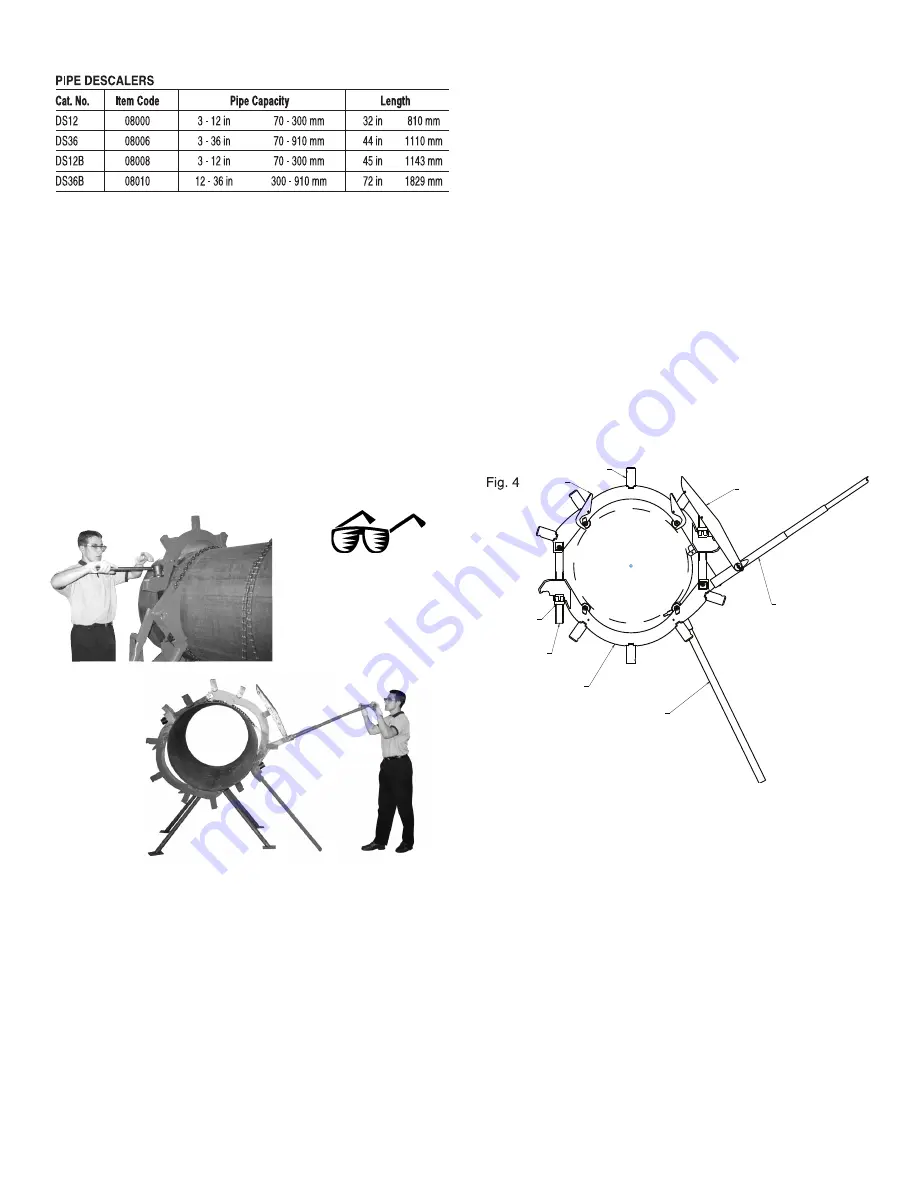

To aid in rotating cutters RC30 and larger, a Ratcheting Mechanism

is included with each cutter. This mechanism consists of a saddle

(or pivot block) that is clamped to the pipe by a chain, a lever handle

and a latch (Figs 4 and 5). As the handle is rotated up, the latch

slides up over the top of a lug on the cutter. When the handle is

rotated down, the latch engages the lug and pulls the cutter around

the pipe.

1. Place upper yoke half (the one with finger guides) on the top

of the pipe. Be sure the round grooves in the lugs are

facing away from the direction of rotation. Align the wheels

over desired cutting line.

2. Attach lower yoke to upper yoke one side at a time by sliding

the main screws into the slots and seating the nuts into

counter bores.

3. Check to see if cutter wheels are over desired cutting line.

Rotate the cutter until the weight of the cutter is resting on

the spring-loaded guide fingers and the two guides are

centered on the top of the pipe. All cutter wheels should at this

time be away from the pipe.

4. Slightly rock and wiggle the cutter until all four of the guide

fingers touch the pipe. This process insures the cutter sits

square on the pipe. Check to see if cutter wheels are centered

over desired cutting line.

5. Next, without disturbing the cutter position, tighten up the

main screw nuts EQUALLY by hand. Usually the two

bottom wheels will contact the pipe first. Continue

tightening as the spring-loaded guide fingers retract and

permit the top wheels to contact the pipe. Using the wrench,

tighten the one accessible nut as tight as possible while still

being able to rotate the cutter.

6.

Set-up for Ratcheting Mechanism

Insert Torque Arm into saddle. Place the saddle on the side

of cutter where the pipe is to remain. Rest the teeth of the

saddle against the pipe and the Torque Arm against the

ground at an angle. Adjust the position of the saddle so

that it is 3-1/8” (79 mm) from the center of cut to the side

of saddle (Fig. 6). Be sure all four teeth of the saddle are

contacting the pipe for proper alignment. Loosen chain

screw nut to the end of the screw, wrap the chain around the

pipe and pull tight. Hook closest chain link into the chain catch

on the opposite end of the saddle. Fully tighten the chain

screw with the provided wrench.

7. Connect ratchet handle to the triangular saddle by inserting

the lower steel pin on the end of the handle into the hole in

the saddle. Secure the handle with the washer and cotter pin

provided.

8. Connect red latch (used to hook around lugs) to ratchet

handle pin. Secure the latch with the other washer and cotter

pin provided. Check to see if the latch is centered over the

cutter.

RATCHETING MECHANISM

GUIDES

LUG

LATCH

HANDLE

TORQUE ARM

MAIN SCREW

NUT

MAIN CUTTER

Fig. 3

NOTE: Check Fig. 7 to see proper RC42 cutter pivot pin position.