Magnetic Sonde

7 Installation and Maintenance

4423

16

Edition:003

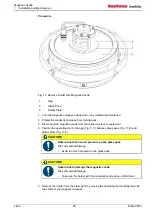

Safety Conditions

WARNING!

Danger due to nonadherence to safety instructions

Risk of death or serious injury and material damage

• Observe all general safety instructions.

• Observe all safety instructions for maintenance.

Procedure

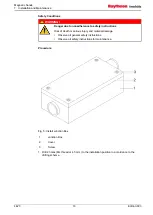

Fig. 5: Install Junction Box

1

Junction Box

2

Cover

3

Screw

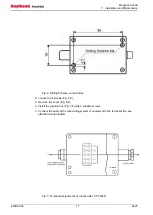

1. Drill 2 holes (M4 thread or 4.5 mm) to the installation position in accordance to the

drilling scheme.

Summary of Contents for 108-010.NG001 E01

Page 6: ...Magnetic Sonde List of Figures 4423 IV Edition 003 ...

Page 8: ...Magnetic Sonde List of Tables 4423 VI Edition 003 ...

Page 10: ...Magnetic Sonde List of Abbreviations 4423 VIII Edition 003 ...

Page 55: ...12 02 10 ...

Page 56: ...07 10 11 Lut 23 11 11 ...

Page 57: ...07 10 11 Lut 23 11 11 ...

Page 58: ...12 01 10 ...

Page 62: ...Magnetic Sonde Illustrated Spare Parts Catalog 4 4 Edition 001 Intentionally left blank ...

Page 73: ...Magnetic Sonde Illustrated Spare Parts Catalog Edition 001 15 4423 Intentionally left blank ...

Page 80: ...Magnetic Sonde Illustrated Spare Parts Catalog 4423 22 Edition 001 Intentionally left blank ...