RG27/35/37 Operation • Service • Maintenance

38

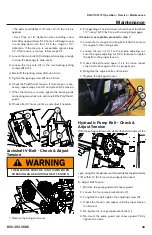

Hydraulic Oil - Check

The hydraulic oil tank (1) (reservoir) is the smaller tank directly

behind the larger tank. The oil level is determined either by

pulling out the dipstick, which is part of the oil filter assembly

on top of the reservoir, or by a visual check. The oil level

should be 1” to 1-1/2” from the top of the reservoir. Add oil

if it is below the level indicated.

Check the oil level only when the engine is cold, and with

the machine on level ground.

Re-fill the hydraulic oil tank (1)

1. Clean all surrounding debris and dirt off of the tank fill

opening area. (Hydraulic fluid must be kept completely

clean!)

2. Unscrew the filter cap and pull out the filter.

A 10 micron filter is used on this machine. It is located

in the reservoir. The oild filter head has a built-in relief

, which can open and bypass th egilter if the oil is

extrememly cold or if the filter becomes clogged. It also

has a service indicator that shows when the filter needs

replaced.

3. Fill the tank until the oil level shows 6 to 7” from the

bottom of the dipstick.

4. Replace the filter and cap.

Changing Hydraulic Oil

Drain the Oil

1. Steam clean the pump, motor, cylinders, hydraulic lines,

fittings, and tank.

2. Place the machine on level ground.

3. Place a container below the hose and fitting located

underneath the hydraulic pump.

4. Remove the hose from the fitting and allow the oil to

drain into the container.

5. Clean and install the hose.

6. Loosen the hose fittings on the cylinders, and drain as

much fluid as feasible.

7. Replace and tighten fittings.

8. Dispose of drained oil according to local environment

protection regulations.

Start Up Procedure

1. Make sure all fittings are tight.

2. Fill the reservoir with the recommended hydrau lic oil (see

“Lubrication and Fluid Specifications”), which should be

passed through a 10 micron (nom i nal) non-bypass filter

prior to entering the reservoir. Never reuse fluid.

3. Crank the engine, using the starter, for a short period

of time. This allows the system to begin filling with fluid.

Start the engine and run at the lowest possible speed.

Shut down the engine within 40 seconds if the pump or

motor begin making an unusual noise, indicating a lack

of oil, and be sure the reservoir is full and all the hoses

are properly connected.

4. Set the engine throttle at approximately 50% of maximum

throttle for a few minutes. This will purge trapped air from

the pump/control valve cir cuit.

5. Cycle the self-propel drive lever, two or three times,

to purge all remaining trapped air from the self-propel

motor circuit.

The hydraulic motor is now ready for operation.

6. Now the hydraulic cylinders circuits may be prepared.

Run the engine at normal operating speed. Using

the cutting boom motion lever, slowly, then at normal

operating speed, cycle the cylinders through all their

motions until all the air is bled off. The motions will be

smooth and powerful when all of the air is bled off.

7. Check the reservoir level, and add more clean fluid if

necessary.

The hydraulic system is now completely ready for

operation.

8. Clean up any spilled hydraulic fluid.

NOTICE

Replace oil if it smells burnt or appears to be dirty.

Use only clean, fresh hyrdaulic oil, free of bubbles.

(Bubbles indicate trapped air.)

2

1

NOTICE

Keep the interior of all hydraulic components

clean as they are installed. The machine must not

be operated without the filter in place, or sever

damage to the major hydraulic compnents will

likely occur.

NOTICE

Prior to filling with fluid, make certain all system

components (reservoir, hoses, valves, fit

tings,

pump, etc.) are clean. Care must be taken to not run

the pump or hydraulic motor without a sufficient

amount of flu id in them.

Maintenance

Summary of Contents for Super Jr RG27

Page 47: ...RG27 35 37 Operation Service Maintenance 800 392 2686 47 Maintenance Notes ...

Page 50: ...RG27 35 37 Operation Service Maintenance 50 Wiring Schematic ...

Page 51: ...RG27 35 37 Operation Service Maintenance 800 392 2686 51 Wiring Schematic ...

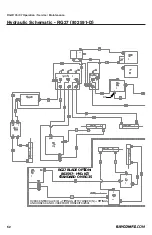

Page 54: ...RG27 35 37 Operation Service Maintenance 54 Hydraulic Schematic RG37 802846 RF T T P P ...

Page 56: ...RG27 35 37 Operation Service Maintenance 56 Specifications SERVICING TAPER BUSHINGS ...

Page 63: ...RG27 35 37 Operation Service Maintenance 800 392 2686 63 ...