RG27/35/37 Operation • Service • Maintenance

800.392.2686

37

Walk-Around Inspection

1. Inspect the cutting boom cylinders and linkage for

damage or excessive wear. Repair if dam aged.

2. Inspect and remove any chip or residue buildup in and

around the engine.

3. Inspect the hydraulic system for leaks. Inspect the tank,

hoses, tubes, plugs, joints, and fittings. Correct any leaks.

4. Be sure the covers and guards are firmly in place. Inspect

for damage.

5. Inspect the tires and rims for damage and inflation. Inflate

all tires to 22 PSI. Replace worn tires.

6. Inspect for loose or missing fasteners. Tighten or replace.

7. Inspect the belts and PolyChain® for wear. Replace if

frayed or cracked.

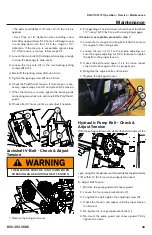

Engine Oil Level

Check oil level on dipstick (1) located behind engine as shown.

Follow the directions found in the Engine Operator Manual.

Engine Oil Cooler - Clean

Check the oil cooler daily and clean as necessary. (Refer to

the engine operation manual for details).

NOTE: For cleaning with a hot water cleaning device,

use a spray steam with a pressure not exceeding 426

psi (2982 kPa) to pre vent damage to painted ar eas of

the components. The use of solvents or strong cleaners

should be avoided for the first 90 days. Strong cleaners

will destroy paint until the paint is fully cured.

After cleaning, blow the oil cooler dry with compressed air

that does not exceed 40 psi (275 kPa).

Engine Oil & Filter - Change

Follow directions in the Engine Operator Manual

1. With engine OFF but still warm, remove the oil drain

plug (2) and drain oil into appropriate container. When

finished, reinstall the drain plug.

2. Remove the oil filter (3) by turning counterclockwise as

shown.

3. Apply a light oil film on the new filter gasket and install

filter by turning clockwise until gasket contacts the filter

adapter. Then tighten by hand 1/2 to 3/4 turn more.

4. Place engine level and add the appropriate oil type and

viscosity rating as described in the engine manual. Fill

to the correct level, replace dipstick and fill cap.

5. Start engine and run for 30 seconds to circulate oil

through the filter, then stop engine.

6. Wait 30 seconds after shutting engine down and then

check oil level and add according to the FULL mark

shown on the dipstick.

7. When complete, replace the dipstick and fill cap.

Engine Spark Plugs - Check

Follow the directions found in the Engine Operator Manual.

• Check the gap using a feeler gage. Adjust gage to 0.030”

(0.76mm) by carefully bending the ground electrode.

• Reinstall the spark plug into the cylinder head. Torque

the spark plug to 18-22 ft lbs (24-29 Nm).

Engine Valve Clearance

Follow the directions found in the Engine Operator Manual

to check valve clearance

Maintenance

NOTICE

Check only when the engine is in a level position.

1

2

3

Summary of Contents for Super Jr RG27

Page 47: ...RG27 35 37 Operation Service Maintenance 800 392 2686 47 Maintenance Notes ...

Page 50: ...RG27 35 37 Operation Service Maintenance 50 Wiring Schematic ...

Page 51: ...RG27 35 37 Operation Service Maintenance 800 392 2686 51 Wiring Schematic ...

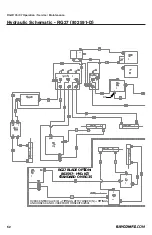

Page 54: ...RG27 35 37 Operation Service Maintenance 54 Hydraulic Schematic RG37 802846 RF T T P P ...

Page 56: ...RG27 35 37 Operation Service Maintenance 56 Specifications SERVICING TAPER BUSHINGS ...

Page 63: ...RG27 35 37 Operation Service Maintenance 800 392 2686 63 ...