RG27/35/37 Operation • Service • Maintenance

800.392.2686

29

Operation

NOTE: The operator control station must not be in the

transport position (locked at the front of the machine)

to operate the blade. The blade will not function in this

position.

Transporting in Freewheel Mode

In the event of a machine malfunction, the stump cutter may be

towed a short distance by using the wheel drive disconnect.

This procedure should be used to move the machine in the

event that it can not power itself to the desired spot to be

repaired. Before using the freewheel disconnect make sure

the wheels are choked.

Disable The Wheel Motors

To disengage the wheel drive motor perform the

following steps:

1. Ensure that the machine is secured and will not roll.

2. On each drive wheel, pull and turn the Wheel Drive

Disconnect (11) handle 90 degrees.

3. The machine is now ready to be moved.

4. Once the proper repairs have been made, the drives can

be re-engaged by pulling and turning the Wheel Drive

Disconnect (11) handle 90 degrees.

Re-engage The Wheel Motors

1. Reopen the valve on the gun. This will allow the charged

hydraulic fluid to drain back into the gun.

2. Disconnect the gun from the brake release fitting using

the wrench.

3. You may now empty the remaining fluid back into the

plastic bottle from the gun.

4. Reconnect hydraulic hose the brake release fitting you

removed earlier in step 3.

5. Tighten the needle valve screw loosened in step 2.

6. If the proper repairs have been made to the machine, you

may follow the starting procedure outline in this manual.

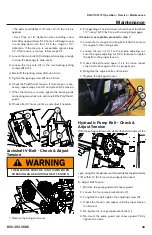

Dual Wheels

The dual wheels provide increased stability & traction, yet

can be easily removed for maneuvering machine through

tight spots. To remove a wheel:

• Drive the rear inside wheel onto a small wooden board

so that the outer wheel is slightly raised off of the ground.

• Loosen the bolt (13) using the provided tool (12).

• Remove the outer wheel.

• Place the outer wheel, washer and bolt in safe-keeping

until needed again.

• To remount the wheel, reverse the above procedure.

Tighten the bolt firmly but do not exceed 80 ft/lbs.

Note: In instances where the above procedure is not possible,

a 4x4 (or similar material) can be placed under the blade to

aid in lifting the machine. Use extreme caution when doing

so as this decreases machine stability.

NOTE: TORQUE BOLTS TO 80 FT-LBS

CAUTION - EXCESSIVE TORQUE WILL

DISTORT BACKING PLATE

12

13

THE MACHINE WILL ROLL FREELY WHEN THE

WHEEL DRIVE DISCONNECT IS USED.

11

Summary of Contents for Super Jr RG27

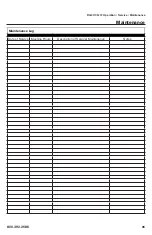

Page 47: ...RG27 35 37 Operation Service Maintenance 800 392 2686 47 Maintenance Notes ...

Page 50: ...RG27 35 37 Operation Service Maintenance 50 Wiring Schematic ...

Page 51: ...RG27 35 37 Operation Service Maintenance 800 392 2686 51 Wiring Schematic ...

Page 54: ...RG27 35 37 Operation Service Maintenance 54 Hydraulic Schematic RG37 802846 RF T T P P ...

Page 56: ...RG27 35 37 Operation Service Maintenance 56 Specifications SERVICING TAPER BUSHINGS ...

Page 63: ...RG27 35 37 Operation Service Maintenance 800 392 2686 63 ...