RG27/35/37 Operation • Service • Maintenance

48

Troubleshooting

Engine

Use the following information to determine the source and

solution to problems you may encounter related to the engine.

This information can also be found in the Kubota Engine

Operator’s Manual that shipped with this machine.

Service

When it is difficult to start the engine

Cause

Countermeasures

Fuel is thick and

doesn’t flow

►Check the fuel tank and fuel filter. Remove

water, dirt, and other impurities.

►As all fuel will be filtered by the filter, if there

should be any water or other foreign matters

on the filter, clean the filter with kerosene.

Air or water

mixed in the

fuel system

►If air is in the fuel filter or injection lines, the

fuel pump will not work properly. To maintain

proper fuel injection pressure, check carefully

for loosened fuel line couplings, loose cap

nut, etc.

►Loosen joint bolt stop fuel filter and air vent

screws of fuel injection pump to eliminate all

the air in the fuel system.

Thick carbon

deposits on

orifice of injec-

tion nozzle

►This is caused when water or dirt is mixed

in the fuel. Clean the nozzle injection place

being careful not to damage the orifice.

►Check to see if the nozzle is working prop-

erly or not. If not, install a new nozzle.

Valve clearance

is wrong

►Adjust the valve clearance to 0.145 to 0.185

mm (0.0057 to 0.0072 in.) when the engine

is cold

Leaking valves

►Grind valves.

Fuel injection

timing is wrong

►Adjust injection timing

The injection timing 0.3 rad (18°) before top

dead center.

Engine oil

become thick

in cold weather

and engine

cranks slow

►Change grade of oil according to the

weather (temperature)

Low Compres-

sion

►Bad valve or excessive wear of rings, pis-

tons, and liners cause insufficient compres-

sion. Replace with new parts.

Battery is

discharged and

the engine will

not crank

►Charge battery.

►In winter, always remove battery from the

machine, charge fully and keep indoors.

Reinstall in machine at times of use.

When engine suddenly stops

Cause

Countermeasures

Lack of fuel

►Check the fuel tank and refill with fuel, if

necessary.

►Also check the fuel system for air or leaks.

Bad nozzle

►If necessary, replace with a new nozzle.

Moving parts

are overheated

due to shortage

of lubrication

oil or improper

lubrication

►Check amount of engine oil with oil level

gauge.

►Check lubricating oil system.

►At every 2 times of oil change, the oil filter

cartridge should be replaced.

►Check to see if the engine bearing clear-

ances are within factory specs..

When output is insufficient

Cause

Countermeasures

Carbon stuck

around orifice of

nozzle place

►Clean orifices and needle valve being very

careful not to damage the nozzle orifice..

►Check nozzle to ensure that It is good. If

not, replace the nozzle..

Compression is

insufficient.

Leaking valves

►Bad valve and excessive wear of rings,

pistons, and liners cause insufficient com-

pression. Replace with new parts..

►Grind valves..

Fuel is insuf-

ficient

►Check fuel system..

Overheating of

moving parts

►Check lubricating oil system.

►Check to see if lubricating oil filter is work-

ing properly.

►Filter element deposited with impurities

would cause poor lubrication. Change

element.

►Check that the clearance of bearings are

within factory specs.

►Check injection timing.

Valve clearance

is wrong

►Adjust the valve clearance to 0.145 to

0.185 mm (0.0057 to 0.0072 in.) when the

engine is cold

Air cleaner is

dirty

►Clean the element every 100 hours of

operation.

Fuel injection

pressure is

wrong

►Adjust to proper pressure:

13.7 Mpa (140kgf/cm2, 1991 psi)

Injection pump

wear

►Do not use poor quality fuel as it will cause

wear of the pump. Only use No.2-D diesel

fuel.

►Check the fuel injection pump element

and delivery valve assembly and replace as

necessary.

When color of exhaust is especially bad

Cause

Countermeasures

Fuel governing

device bad

►Contact dealer for repairs.

Fuel is

extremely poor

quality

►Select good quality fuel.

Use No.2-D diesel fuel only..

Nozzle is bad

►If necessary, replace with a new nozzle.

Combustion is

incomplete

►Cause is poor atomization, improper

injection timing, etc. Because of trouble in

injection system or in poor valve adjustment

or compression leakage, poor compression,

etc. Check for cause..

Summary of Contents for Super Jr RG27

Page 47: ...RG27 35 37 Operation Service Maintenance 800 392 2686 47 Maintenance Notes ...

Page 50: ...RG27 35 37 Operation Service Maintenance 50 Wiring Schematic ...

Page 51: ...RG27 35 37 Operation Service Maintenance 800 392 2686 51 Wiring Schematic ...

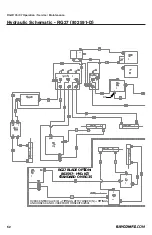

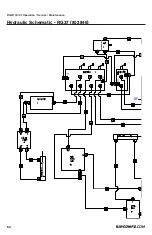

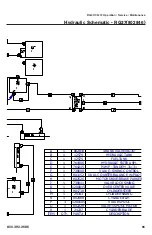

Page 54: ...RG27 35 37 Operation Service Maintenance 54 Hydraulic Schematic RG37 802846 RF T T P P ...

Page 56: ...RG27 35 37 Operation Service Maintenance 56 Specifications SERVICING TAPER BUSHINGS ...

Page 63: ...RG27 35 37 Operation Service Maintenance 800 392 2686 63 ...