ROUBLESHOOTING

T

10

6823346-R3

6

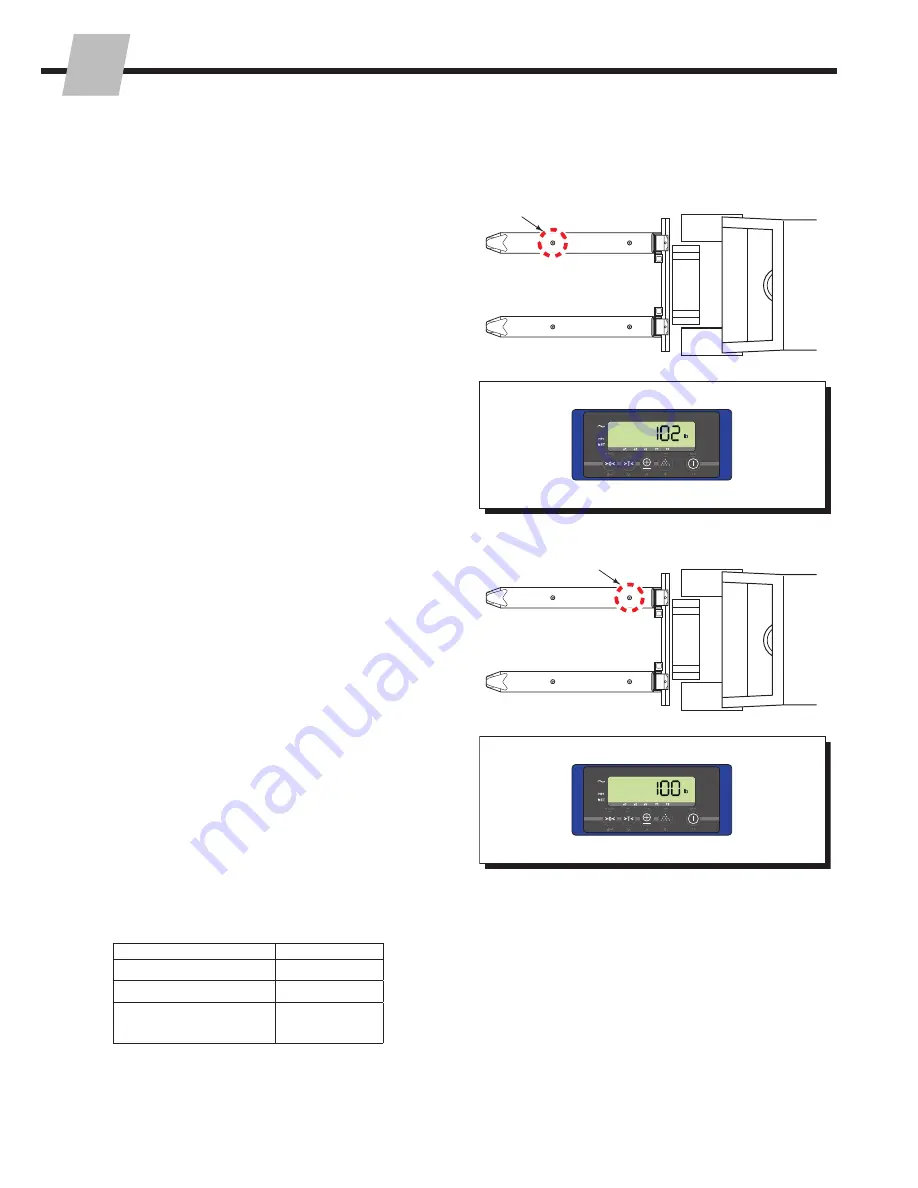

Move the weight to position C, as shown.

7

Note the weight shown on the display.

8

Move the weight to position D, as shown.

9

Note the weight shown on the display.

10

If the any of weights are not within weight ±

A

(chart

below) of each other, the load cell may require further

troubleshooting or service. Contact Cascade Service

department. Refer to the back cover of this manual.

iFork Capacity

Weight 'A'

5000 lb. (2268 kg)

2 lb. (1 kg)

6000 lb. (2722 kg)

2 lb. (1 kg)

10,000 lb. (4536 kg)

2 lb. (1 kg)

1

5 lb. (2 kg)

2

1

Use this value if the weight used for the procedure is

less

than 1000 lb (543.6 kg).

2

Use this value if the weight used for the procedure is

greater

than 1000 lb (543.6 kg).

2.3-2

Check Weight Readout At

Each Load Cell

(continued)

FK0256.eps

6

7

9

8

Position C

Position D