GB

Page 56 of 64

INSTRUCTION, USE AND

MAINTENANCE MANUAL

1

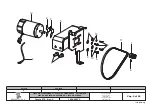

Turn the gauge ferrule (

Fig. 117 ref. 1

) on the inner

edge of the wheel UPWARDS and press “F4”.

Fig.

117

1

KEY

1 – Exit from the gauge calibration procedure and

return to calibration menu page (RED) (F1)

2 – Perform storing of gauge position on “inner edge

of the wheel UPWARDS” (GREEN) (F4)

2

Press "CENTRE" to confirm. Calibration of the distance

and diameter calipers is terminated, The program will

display again the calibration menu page in

Fig. 105

.

1

KEY

1 – Return to previous screen page (RED) (F1)

2 – Perform storing of gauge position (CENTRAL)

2

Fig. 118

IF THE AUTOMATIC RIM WIDTH

MEASURING DEVICE IS ENABLED,

THE CALIBRATION PAGE WILL

APPEAR FOR THIS DEVICE (SEE

PARA. 21.4).

21.4 Automatic rim width measuring device

calibration (optional)

After performing distance and diameter caliper calibra-

tion (see para. 21.3) if the automatic rim width measur-

ing device is enabled, the following page will appear:

1

KEY

1 – Exit from the width measurement calibration

procedure and return to calibration menu page

(RED) (F1)

2 – Perform storing of width measuring device posi-

tion on "end of shaft" (GREEN) (F4)

2

Fig. 119

Move the tip of the width measuring device (

Fig. 120A

ref. 1

) by the mandrel end (

Fig. 120A ref. 2

) (in case

of pneumatic mandrel, move it next to upper edge of

the closed mandrel). The program will show the screen

page in

Fig. 120B

.

G2.124R - GP2.124R

RAVAGLIOLI S.p.A.

1297-M010-0_R