d. Remove the ribbon cable (1657-0200) from power supply (at V-J1)

and main board (at C-J1). Notice that the connectors are symmetrical and

reversible; and the cable is

extra long, for convenience in servicing.

The next step, removal of the power supply, is NOT related to the

removal of the main board. Either can be left in place whi Ie the other is

removed.

e. Remove the 4 screws that pass vertically through the corners of the

power supply into the main chassis. Lift the power supply slightly and

move it back carefully while disengaging

the POWER pushbutton extension from its hole in the front

panel (Figure 5-3). Reassembly note: 4 screws,

8 mm long.

f. After disconnecting the ribbon cable, provide a convenient

"upsidedown" support by reinstalling the top cover, temporarily. Turn the

instrument, bottom up.

g. Remove 4 screws from the bottom shell, one near

each rubber foot. Slide the bottom shell back (or forward), free of the

main chassis (Figure 5-4). Reassembly notes: Be sure to enfold the pliable

dirt seals at left and right sides of main chassis as you start to slide bottom

shell onto main

chassis; use 4 screws, 8 mm long.

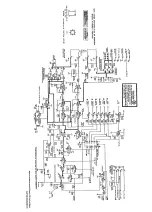

h. Remove 8 screws shown in Figure 5-5 as ABCGHI

(7 mm) and EJ (8 mm). Lift the rear edge of the main board as shown in

Figure 5-6 and slide it back until clear of the main chassis.

i. For access to the test-fixture contacts, which are on the main board,

remove screws K L and drop the test-fixture guide block off of the test

fixture contacts. Refer to bottom interior view, Figure 5-5.

5-8 SERVICE

Notice that it is possible to remove the main board with the display

board mounted on it, by this procedure: release all 8 front push buttons;

remove screws ABCEGHIJ; lift

rear edge of main board 25 mm and slide it forward 16 mm; lift rear edge to

75 mm (so display board clears cutout in main chassis) and slide the

assembly back until display board reaches spacer; lift rear edge another 15

mm and slide it back until push buttons are free; lift assembly out.

Reassembly note: install screw "I," loosely. Position test fixture as

desired (preferably symmetrical in its opening), before installing screws A,

E, etc.

Summary of Contents for 1657 RLC Digibridge

Page 6: ...Table of Contents...

Page 8: ...1 2 INTRODUCTION...

Page 9: ...INTRODUCTION 1 3...

Page 10: ...1 4 INTRODUCTION...

Page 15: ...OPERATION 3 1...

Page 24: ...4 2 THEORY...

Page 30: ...5 4 SERVICE...

Page 42: ...5 16 SERVICE...

Page 46: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......