14

7080-162B

October 12, 2017

MT VERNON E2-C

B. Avoiding Smoke and Odors

Negative Pressure, Shut-Down and Electrical Power

Failure

To reduce the probability of back-drafting or burn-back in

the pellet appliance during power failure or shut down con-

ditions, it must be able to draft naturally without exhaust

blower operation.

Negative pressure in the house will resist this natural draft if

not accounted for in the pellet appliance installation.

Heat rises in the house and leaks out at upper levels. This

air must be replaced with cold air from outdoors which flows

into lower levels of the house.

Vents and chimneys into basements and lower levels of the

house can become the conduit for air supply and reverse

under these conditions.

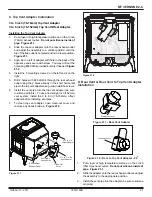

Outside Air

An outside air kit (OAK-3) is recommended in all installations

and must be ordered separately.

Per national building codes, consideration must be given to

combustion air supply to all combustion appliances. Failure

to supply adequate combustion air for all appliance demands

may lead to back drafting of those and other appliances.

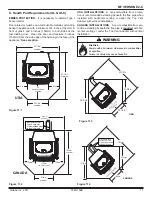

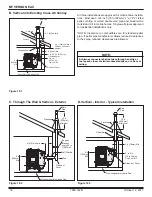

When the appliance is roof vented (strongly recommended):

The air intake is best located on the exterior wall oriented

towards the prevailing wind direction during the heating

season.

When the appliance is side-wall vented:

The air intake is best located on the same exterior wall as

the exhaust vent outlet and located lower on the wall than

the exhaust vent outlet.

The outside air supply kit can supply most of the demands of

the pellet appliance, but consideration must be given to the

total house demand.

House demand may consume the air needed for the appli-

ance. It may be necessary to add additional ventilation to

the space in which the pellet appliance is located.

Consult with your local HVAC professional to determine the

ventilation demands for your house.

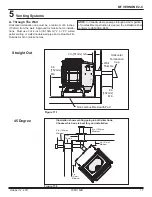

Vent Configurations

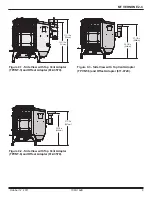

When installing a pellet appliance with a horizontal vent con-

figuration the frequency of power outages should be consid

-

ered:

• Power outages during operation will cause the appliance

to immediately turn off and may create conditions where

smoke will back draft into the house. In order to reduce

the likelihood of smoke back drafting into the house

during a power outage, Hearth and Home Technologies

strongly suggests:

• Installing the pellet venting with a minimum vertical

run of 5 feet (1.52m).

• Installing the outside air kit at least 4 feet (1.22m)

below the vent termination.

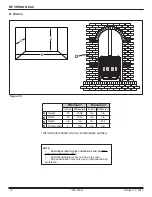

To prevent soot damage to exterior walls of the house and to

prevent re-entry of soot or ash into the house:

• Maintain specified clearances to windows, doors and

air inlets, including air conditioners.

• Vents should not be placed below ventilated soffits.

Run the vent above the roof.

• Avoid venting into alcove locations.

• Vents should not terminate under overhangs, decks or

onto covered porches.

• Maintain minimum clearance of 12 inches (305mm)

from the vent termination to the exterior wall. If you

see deposits developing on the wall, you may need to

extend this distance to accommodate your installation

conditions.

CAUTION

• DO NOT CONNECT THIS Appliance TO A CHIMNEY

FLUE SERVICING ANOTHER APPLIANCE.

• DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT

OR SYSTEM.