QSA Global, Inc.

40 North Avenue Burlington, MA 01803

888.272.2242

781.272.2000

qsa-global.com

Operations Manual

MAN-038 March 2019

Page 63 of 100

Rust (red oxide) on the inner and outer core of the cable.

Uniformity of the spacing between the outer helical windings of the cable. Check for flattened

areas and excessive wear that reduces the cable's outer diameter less than 0.183 in (4.7

mm).

Perform a flexibility (spring) test of the cable by bending the connector end of the cable into a

‘U’ shape and then releasing it. A cable that is bent / released and does not spring back into

an essentially straight shape is indicative of internal corrosion of the cable. A ‘crunching”

feeling and stiffness when bending the cable into the “U” shape is another confirmation of the

problem. The drive cable must be removed from service.

Carefully examine the drive cable in the area of the control crank assembly looking for cuts,

breaks of the inner and outer spiral metal windings, fraying, rust, unusual stiffness and

uniformity of the spacing between the outer spiral windings.

Examine the entire length of cable looking for defects described above.

If a control cable is deemed as defective during this inspection, remove it from service and tag it

with a label to prevent inadvertent use.

The control cable (Model 550 male) connector must be replaced at intervals

not to exceed five

(5) years

. Maintenance program administrators must maintain traceability records (lot numbers)

for replacement of all “Safety Class A” designated components.

h.

Lightly lubricate the control cable using MIL-G-23827B (or C), MIL-PRF-23827C, or equivalent

grease. Apply additional grease to the first 3 ft (approximately 1m) of control cable (male connector

end).

i.

Clean the exterior of the remote control conduits using clean rags and a detergent. Remove all dirt

and grease from the polyvinyl conduits and swaged fittings. Carefully inspect the entire length of

remote control conduits for cuts and melted areas. Repairs to cut or melted areas can be

accomplished by taping the area with 3M™ yellow polyvinyl tape (or black polyvinyl electrical tape).

The tape will prevent the ingress of water and other liquid that would cause corrosion of the remote

control drive cable. Visually inspect and feel for dents and inward depressions on the remote control

conduits. The extreme control conduits are dent resistant, but may have flattened areas or cuts due to

impacts.

Remove the spring duplex strain relief assembly and examine the control conduits where they

protrude from the swage fittings, looking for bulges or cracks in the polyvinyl. Remote control conduits

with large dented areas or cracks/ bulges near the swage fittings must be sent to the manufacturer or

authorized service center for repairs.

Clean the interior of both remote control conduits by pouring 4-5 oz (100 ml) of clean solvent into one

end. Use compressed air to blow the solvent through the entire length of conduits into a clean white

cloth attached to the opposite end. Repeat this cleaning process until the solvent blown through the

conduit comes out clean. Use the compressed air to thoroughly dry the interior of the conduit.

Residual solvent left in the remote control conduit will dilute the lubrication applied to the remote

control cable diminishing the protective qualities.

Check the swage fittings to ensure the threads and hex nuts are not stripped and are clean. Using

your hands, attempt to twist or rotate the swage fittings off the control conduits. If any movement is

possible, the control conduit must be removed from service and new swage fittings must be installed.

j.

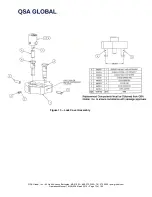

Remove the crank arm assembly with brake from the control crank assembly by removing the 5/16

inch hex bolt and washer. Check the hand crank knob (tee-handle) pin (part number 95010) for

looseness or excessive wear. Replace worn knob pin by removing roll-pin (part number PIN024),

replace knob pin (part number 95010) and then insert a new roll pin (part number PIN024). Check

brake assembly for proper on and off operation and verify the spring tension is adequate to maintain