- 78 -

9 Lubrication system

Preparation data -----------9.1

Fault diagnosis ------------9.2

Oil pump -------------------9.3

9.1 Preparation data

Matters needing attention in operation

After dismantling the oil pump, all the components should be carefully cleaned and their surfaced should be

cleared by high-pressure gas.

When dismantling the oil pump, pay attention to prevent foreign matters from falling into the crankcase.

Function of the lubrication system

:

supplying lubricating oil to the wear surface to reduce part wear by turning dry

friction between surfaces into liquid friction between lubricating oil particles

;

cooling high-load parts

;

absorbing impact

from the bearing and other parts and reducing noises

;

increasing air tightness between the piston ring and cylinder wall

;

cleaning and carrying away impurities on part surfaces.

Preparation reference

Item Standard

Permitted

limit

when changing the oil

0.9L

/

machine oil

capacity

when dismantling

1L

/

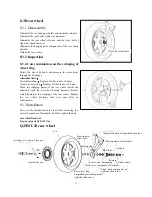

Dial clearance between the outer and inner rotors.

0.04

-

0.15 0.20

Clearance between the outer rotor and the pump body.

0.15

-

0.21 0.21

lubricating

pump rotator

Rotor end clearance

0.07-0.12

0.18

9.2 Fault diagnosis

Decrease of machine oil Engine burnt out

Natural loss of machine oil Absence of oil or oil pressure too low

Machine oil leak Oil path blocked

Wear and improper installation of the piston ring Machine oil not used

Summary of Contents for QJ150T-10

Page 15: ... 14 QJ150 10 ...

Page 73: ... 72 Rear wheel rear suspension ...

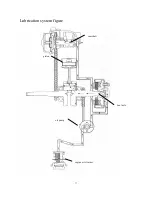

Page 78: ... 77 Lubrication system figure engine oil strainer oil pump bent axle camshaft piston ...

Page 87: ... 86 ...

Page 97: ... 96 ...

Page 104: ... 103 ...

Page 113: ... 112 Output axle Middle axle Input axle ...

Page 116: ... 115 The assembly of bearings and oil seal should use special tools to prevent damage ...

Page 125: ... 124 Muffler ...

Page 131: ... 130 ...