- 59 -

2.

Brake

pad

worn

out

2.

Brake

pad

worn

out

3. Improper installation of brake pad

3. Improper installation of brake pad

4. Brake pad, hydraulic brake polluted

Strange sound in braking

1. Brake pad worn out

2. Brake pad, hydraulic brakepolluted

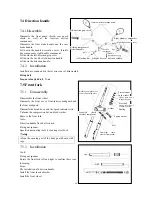

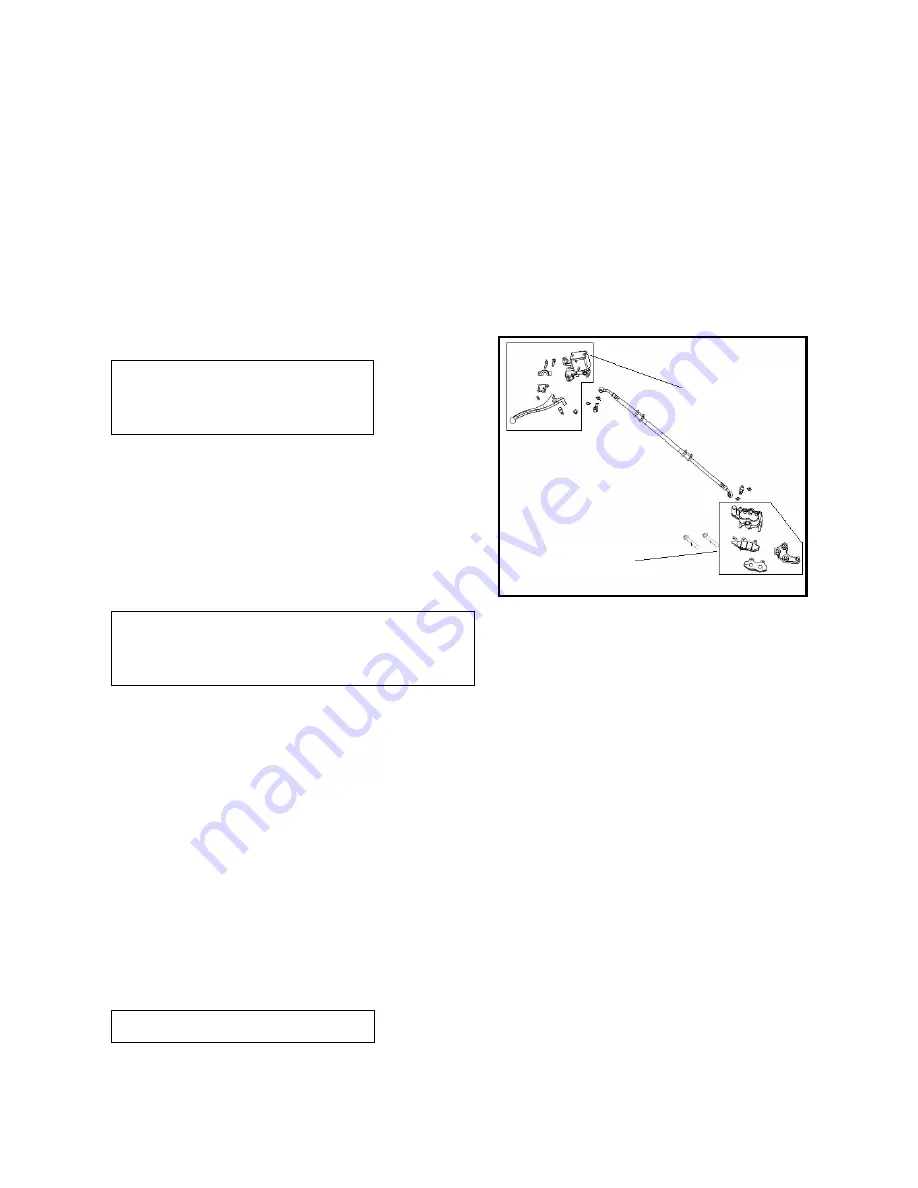

5.3 Front hydraulic brake

5.3.1 Disassembly

*Note

•Always replace the brake pad in pairs.

•If a brake pad is reused, mark a signal

on its side before disassembly so that it

can be installed to the original position.

Dismantle the following components from the front absorber

Front brake:

1. Brake cylinder component

2. Brake hose assembly of the front brake

3. Brake clutch component

4. Front liquid brake link plate

Note: Detailed decomposition map can be seen on P56

* Note

•The braking components can not be spoiled by oil stain

in installation or disassembly.

•Rinse with stipulated cleaning agent in order to avoid

reduction of braking quality.

Unclamp the fixed bolt of the brake cylinder components.

antle the following components from the front absorber.

Disassemble the front wheel spindle.

Unload the front wheel.

Remove the brake disk from the front wheel.

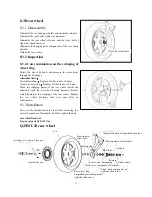

5.3.2 Inspection

Inspect whether the brake pad is worn out and

replace it if necessary.

Measure the brake pad and brake disc and put down the

maximal value.

Specification

Q150T-10

diameter of front hydraulic brake

φ

240mm

diameter of front hydraulic brake

4.0mm

*Note

•It must be measured with microcaliper.

Oil pump body component

Brake cylinder component

Summary of Contents for QJ150T-10

Page 15: ... 14 QJ150 10 ...

Page 73: ... 72 Rear wheel rear suspension ...

Page 78: ... 77 Lubrication system figure engine oil strainer oil pump bent axle camshaft piston ...

Page 87: ... 86 ...

Page 97: ... 96 ...

Page 104: ... 103 ...

Page 113: ... 112 Output axle Middle axle Input axle ...

Page 116: ... 115 The assembly of bearings and oil seal should use special tools to prevent damage ...

Page 125: ... 124 Muffler ...

Page 131: ... 130 ...