- 104 -

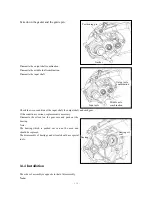

13 Drive disk/Clutch/Driven Wheel

Preparation data -------13.1 Clutch/Driven Wheel -----------------------------13.5

Fault diagnosis---------13.2 Disassemble the clutch and the driven wheel -13.6

left crankcase cover --13.3 Installation------------------------------------------13.7

drive disk --------------13.4

13.1

Preparation data

Matters needing attention in operation

In the operation, there should be no grease on the surface of the triangle belt. Otherwise remove it to

reduce the skidding between the triangle belt and belt wheel to the lowest.

Function:

the drive disk, clutch and the driven wheel compose the steeples speeder. The torque between the dive

disk and the driven wheel is transmitted through the triangle belt.

Preparation reference

Unit

:

mm

Item

Standard value

Allowable limit

the right half of the internal diameter of the drive wheel

28-28.02

28.04

the external diameter of sliding sleeve

23.967-23.98

23.98

width of the triangle belt

21.2

-

22.8 22.8

thickness of the friction plate of clutch

1.5

1.5

the internal diameter of outer sleeve of clutch

125

-

125.2 125.5

the free length of clutch-pressing spring

69±1

70

the external diameter of right-half shaft sleeve of the driven wheel

42.92-42.98

42.90

the external diameter of right-half sliding sleeve of the driven wheel

33.95

-

33.975 34.00

the external diameter of the rolling ball

20-20.2

19.5

13.2

Fault diagnosis

The motor can not move

after the engine is started

The horsepower is not sufficient There is shaking in

the movement

the triangle belt is worn out

the triangle belt is worn out

the friction-plate spring of

clutch is broken out.

the driven wheel is worn out

the clutch spring is deformed

the clutch friction plate is damaged

or worn out

the ball bearing is worn out

the clutch spring is broke

the surface of the driving pulley is stained.

Summary of Contents for QJ150T-10

Page 15: ... 14 QJ150 10 ...

Page 73: ... 72 Rear wheel rear suspension ...

Page 78: ... 77 Lubrication system figure engine oil strainer oil pump bent axle camshaft piston ...

Page 87: ... 86 ...

Page 97: ... 96 ...

Page 104: ... 103 ...

Page 113: ... 112 Output axle Middle axle Input axle ...

Page 116: ... 115 The assembly of bearings and oil seal should use special tools to prevent damage ...

Page 125: ... 124 Muffler ...

Page 131: ... 130 ...