15

4 Mounting

VEGASON 62 • Profibus PA

28785-EN-150603

d

d

h

100 mm/4"

150 mm/6"

200 mm/8"

300 mm/12"

400 mm/16"

500 mm/20"

h

Fig. 8: Deviating socket dimensions

In liquids, direct the sensor as perpendicular as possible to the prod

-

uct surface to achieve optimum measurement results.

Fig. 9: Alignment in liquids

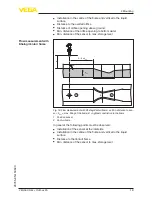

To reduce the min. distance to the medium, you can also mount VE

-

GASON 62 with a beam deflector. By doing this, it is possible to fill the

vessel nearly to maximum. Such an arrangement is suitable primarily

for open vessels such as e.g. overflow basins.

~200

~400x40

0

45°

Fig. 10: Beam deflector

The ultrasonic sensor should be installed at a location where no

installations cross the ultrasonic beam.

Vessel installations such as for example, ladders, limit switches, heat

-

ing spirals, struts etc. can cause false echoes that interfere with the

useful echo. Make sure when planning your measuring site that the

ultrasonic signals have a "clear view" to the measured product.

In case of existing vessel installations, a false echo storage should be

carried out during setup.

Sensor orientation

Vessel installations