62

516514

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

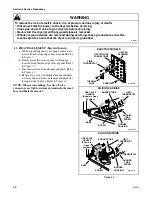

h. Pull assembly forward and disengage the

middle exhaust duct.

i. Rotate the assembly 90° counterclockwise and

slide out through front of dryer.

j. Motor pulley and idler pulley assemblies.

Refer to Figure 47 for motor and idler pulley

removal.

NOTE: When repairing or replacing the idler arm,

it is important to make sure the idler arm moves

freely. To ensure that the idler arm can move freely,

proceed as follows:

(1) Unhook idler spring.

(2) Lift idler arm approximately 3 inches and

release. If idler arm does not fall back to the

base of the motor mount, then idler arm

bolt is too tight.

(3) Loosen idler arm bolt 1/4 turn.

(4) Add grease between idler arm and motor

mount.

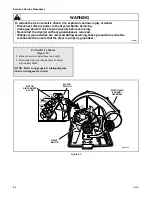

k. Impeller and housing.

(1) Remove screws holding cover to housing.

Refer to Figure 46.

(2) Hold motor pulley securely and unthread

impeller from motor shaft (right hand

thread). Use a 7/8 inch, 6 point socket to aid

in the removal of the impeller.

(3) Remove three screws holding the exhaust

housing to the motor mounting bracket.

Refer to Figure 49.

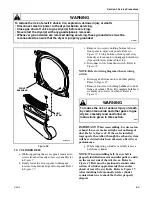

l. Motor

(1) Disengage motor wire harness terminal

block from the motor by pressing in on the

movable locking tabs (located on each side

of the terminal block) and pulling away

from motor. Refer to Figure 50.

IMPORTANT: To avoid an open circuit, DO NOT

pull on the terminal block wires when removing

blocks from motor as this could damage the wires or

terminal crimping.

Before attaching wire harness terminal block to

motor, be sure all the male terminals on motor are

straight and are capable of accepting the terminals

from the wire harness terminal block.

(2) Pry two motor clamps off motor mounting

bracket with screwdriver. Refer to

Figure 48, then lift motor out of mounting

bracket.

Figure 49

EXHAUST HOUSING

ATTACHING SCREWS

D402SE1A

Figure 50

LOCKING

TABS

MOTOR

WIRE HARNESS

CONNECTION BLOCK

D250SE3A

Summary of Contents for DAM 9

Page 1: ...DAM 9 SERVICE MANUAL INDUSTRIAL DRYERS PUBLICATION DATE 02 01 516514 ...

Page 2: ......

Page 127: ......

Page 128: ......