516514

15

Section 3 Troubleshooting

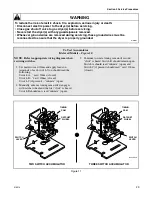

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

11. HEATER ASSEMBLY OR BURNER DOES NOT SHUT OFF

12. CLOTHES DO NOT DRY

POSSIBLE CAUSE

TO CORRECT

Improper motor switch. (Timer must be in a heat

setting.)

• Test switch and replace if inoperative.

Motor does not stop.

• Refer to Paragraph 4.

Incorrect wiring.

• Refer to wiring diagram.

Heater assembly shorted.

• Remove heater assembly and check for short.

POSSIBLE CAUSE

TO CORRECT

Heater assembly does not heat or burner does not

ignite.

• Refer to Paragraph 5.

Too much water in articles being dried.

• Remove excess water.

Laundry load too large.

• Remove part of load. A normal washer load is a normal

dryer load. Maximum load: Dryer cylinder one half full of

wet clothes.

Laundry load too small.

• Add one or two bath towels to load.

Excessive lint on lint filter.

• Clean lint filter.

Heat selector switch set on FLUFF or inoperative.

• Reset switch or timer, or test and replace the switch or

timer if inoperative.

Improper or inadequate exhaust system.

• See Installation Instructions (supplied with dryer) for

exhaust requirements.

Heater assembly or burner shuts off prematurely.

• Refer to Paragraph 9.

Gas Models: Gas line pressure too high or too low.

• If Natural Gas line pressure to dryer exceeds 8 inch water

column pressure, or is lower than 4 inch water column, ask

Gas Company to correct.

Improper belt installation (Low RPM).

• Check for proper installation. Refer to Figure 47.

Summary of Contents for DAM 9

Page 1: ...DAM 9 SERVICE MANUAL INDUSTRIAL DRYERS PUBLICATION DATE 02 01 516514 ...

Page 2: ......

Page 127: ......

Page 128: ......