Service Manual

Chapter 2 - Installation

Battery Installation

2 - 9

3x3 UPS Installation

Issue 2 - November 2001

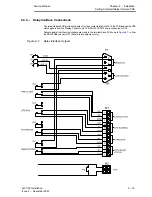

2.3.3 - Installing the Battery Upgrade Kit

Note: Installation of a battery upgrade kit must only be carried out by a suitably

qualified, manufacturer approved engineer.

Kit Contents

Prior to installing the battery upgrade kit thoroughly check the items for damage and ensure that they

are in a serviceable condition.

Check that the battery kit contains the following items:

Item Description

Part Nº

Quantity

Mylar insulating sheet

CM 0319

3

Battery tray

CM 0470

3

Battery retaining bracket

CM 0743

3

Lexan protection

CM 0101

3

Battery cable harness

OS 001

1

Adhesive foam strip

?

ć

Cable holder self adhesive

?

9

Label `High Voltage'

?

3

Note: The 32 battery blocks are not included in the upgrade kit Part Nº

BATTCABLE, but are supplied separately as Battery Kit Part Nº

INTBATT.

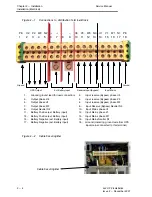

Figure 2-5

Battery Tray Assembly

Mylar Insulating Sheet

Battery Blocks

(links fitted)

Lexan protection strip

Cable Holder

Battery Tray

Battery Cable

Retaining

Bracket

Foam Strip

Battery Tray

Mylar Insulating Sheet

(fold to fit batteries)

Battery Cable Connector

(Secure to retaining

bracket with cable tie)

Retaining Bracket

Cable Holder

Lexan protection strip