Warning:

1. Remove your finger from the trigger when not firing fasteners. Never

carry the tool with a finger on the trigger or an unintended fastener could

be fired.

2. Keep the tool pointed in the right direction at all times.

3. Never attempt to drive the fasteners into material that is too hard or at too

steep an angle. The fasteners can ricochet, causing personal injury. You

cannot drive the fastener near the edge of the workpiece.

4. Disconnect the tool from the air supply before performing maintenance,

clearing a jammed fastener, leaving the work booth, removing the tool to

another position and when not in use.

5. Inspect and clean the tool each work day. Only use the tool if trigger and

safety system are functional, all screws and caps are tight with no leaking

air, and no parts needing repairs.

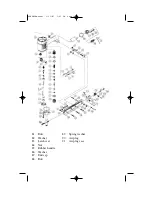

Maintenance

Clean and lubricate the tool daily.

Regular lubrication: Unless using an automatic in-line oiler, place two to six

drops of pneumatic air tool oil into the air inlet before each work day or after

2 hours of continuous use, depending on work and fasteners. Lack of oiling,

or the use of excessive or the wrong kind of oil can damage internal parts.

Check and change all worn or damaged o-rings and seals.

Inspect trigger and safety mechanism to assure safety system is complete and

functional: no loose or missing parts, no blinding or sticking parts.

Tighten all the screws and caps to prevent personal injury.

8006020manual 1/31/07 3:23 PM Page 7