SD700

POWER ELECTRONICS

28

DESCRIPTION OF PROGRAMMING PARAMETERS

3.6.8.

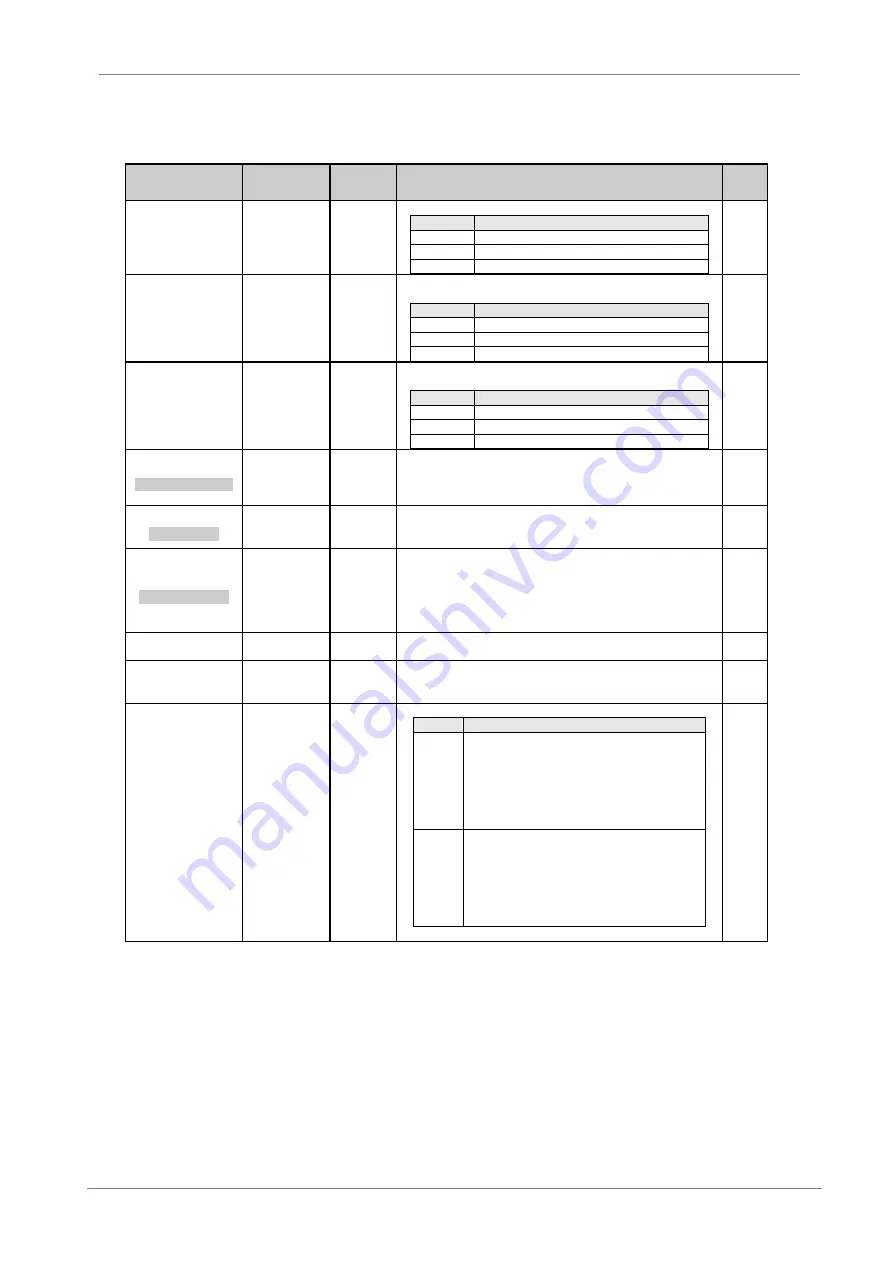

Subgroup 25.2 – S25.2: PID Setting

Parameter

Name /

Description

Range

Function

Set on

RUN

1 PID SETP=LOCAL

G25.2.1

/ PID

setpoint source

LOCAL

AI1

AI2

Selects the input source for the PID setpoint. See the following table:

OPT.

FUNCTION

LOCAL

Reference signal from keypad.

AI1

Reference signal from Analogue Input 1.

AI2

Reference signal from Analogue Input 2.

NO

2 PID aSTP=LOCAL

G25.2.2

/

Alternative PID

setpoint source

LOCAL

AI1

AI2

Selects the input source to introduce the alternative PID setpoint. See the

following table:

OPT.

FUNCTION

LOCAL

Reference signal from keypad.

AI1

Reference signal from Analogue Input 1.

AI2

Reference signal from Analogue Input 2.

NO

3 PID FBK=AI2

G25.2.3

/ PID

feedback source

AI1

AI2

PULSE

Selects the input source for the system feedback signal. See the following

table:

OPT.

FUNCTION

AI1

Feedback signal from Analogue Input 1.

AI2

Feedback signal from Analogue Input 2.

PULSE

Pulses from programmable digital input.

NO

4 PID Kc=1.0

PROPORTIONAL PID

G25.2.4

/

Proportional gain

of PID regulator

0.1 – 20

Allows the user to set the proportional gain value of the PID. If it is

necessary to have a higher control response, then increase this value.

Note:

If this value is increased too much, a higher instability can be

introduced in the system.

NO

5 PID It=5.0s

INTEGRAL PID

G25.2.5

/ Integral

time of PID

regulator

0.1 – 999.9s,

Max.

Allows the user to set the integral time of the PID. If you need a higher

accuracy you should increase this value.

Note:

As this value is increased the system response will slow.

YES

6 PID Dt=0.0s

DIFFERENTIAL PID

G25.2.6

/

Derivation time of

PID regulator

0.0 – 250s

Allows the user to set the derivative time of the PID. A higher system

response can be achieved by increasing this value.

Note:

If this value is increased too much accuracy can be reduced

slightly.

Note:

We recommend do not modify this value since the default setting is

suitable for most pump applications.

YES

7 PID ERR=+xx.x%

G25.2.7

/ Error of

PID regulator

+0 to +100% Displays the difference between the setpoint 'G25.2.1 PID SETP' and the

process feedback signal 'G25.2.3 PID FBK' in percentage.

-

8 ERR=+xx.xxkPa

G25.2.8

/ Error of

PID regulator in

engineering units

+0.0 to +3276

Engin. Units

Displays the difference between the reference 'G25.2.1 PID SETP' and

the process feedback signal 'G25.2.3 PID FBK' in engineering units (Bar,

kPa, m³/s, etc.)

-

9 PID INVERT=N

G25.2.9

/ PID

output inversion

N

Y

It is possible to get an inverse operation of the drive output in PID mode:

OPT.

FUNCTION

N=NO

In this case, the PID response if the feedback

decreases is an increasing of the output speed.

This is the standard setting when the PID is used

for an application of constant pressure control. If

the pressure decreases (feedback) due to a higher

demand, it is required to increase the pump speed

to keep constant the pressure in the system.

Y=YES

In this case, the PID response when the feedback

signal is falling down is a reduction of the output

speed. For example, this operation is typical for a

temperature control by means of PID mode. A

reduction of the temperature (feedback) due to a

lower demand requires that the speed of the fan is

reduced to keep the temperature.

YES

Summary of Contents for SD700 Series

Page 1: ...Variable Speed Drive Application Manual PUMPS...

Page 2: ......

Page 3: ...Variable Speed Drive Application Manual PUMPS Edition March 2011 SD70MTAP01BI Rev B...

Page 4: ...SD700 POWER ELECTRONICS 2...

Page 8: ...SD700 POWER ELECTRONICS 6 INDEX...

Page 61: ......

Page 63: ...www power electronics com...