Powered by Safety

®

11

Installation

IB-50022A

C. S

TORAGE

Since the ground and test device is an

accessory device not normally in continuous

service, it is very important that it be stored

carefully so that it will be available when

needed. The following precautions must be

taken to ensure proper storage of the ground

and test device:

1. The ground and test device must not be

stored in a circuit breaker compartment.

It can only be stored in a storage

compartment.

2. The ground and test device should be

carefully protected against condensation,

preferably by storing it in a warm, dry room

of moderate temperature, such as

40° - 100°F since dampness has an adverse

affect on the insulating parts.

3. The ground and test device should be

stored in a clean location , free from

corrosive gasses or fumes. Particular care

should be taken to protect the device

from moisture and cement dust, as this

combination has a very corrosive affect on

many parts.

4. If the ground and test device is stored for

any length of time, it should be inspected

periodically for rust and to ensure it is

in good mechanical condition. Should

the ground and test device be stored

under adverse conditions, it should be

cleaned and dried before performing the

commissioning tests and before placing the

ground and test device into an energized

circuit breaker compartment.

D. P

REPARING

THE

E

LECTRICALLY

O

PERATED

G

ROUND

AND

T

EST

D

EVICE

FOR

U

SE

Before shipment from the factory, all functions

of the ground and test device are thoroughly

checked. Powell recommends that prior to

each use the ground and test device should be

thoroughly checked and the following tests be

performed in the sequence listed below:

1. High Voltage Insulation Integrity

2. Vacuum

Integrity

3. Control Voltage Insulation Integrity

4. Electrical Operation Check

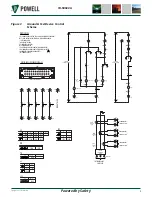

1) High Voltage Insulation Integrity

The primary circuit insulation on the

ground and test device may be checked

phase-to-phase and phase-to-ground

using a 2500V insulation resistance tester.

Since definite limits cannot be given for

satisfactory insulation values when testing

with an insulation resistance tester, a record

should be kept of the insulation resistance

tester readings, as well as the temperature

and humidity readings. The records should

be used to detect any weakening of the

insulation system from one check period to

the next.

To check insulation integrity, the AC high

potential test described below is strongly

recommended.

The ground and test device insulation

should be tested with the ground and test

device vacuum interrupter contacts in

the open position. Test each pole of the

ground and test device separately with the

other two poles and the frame grounded.

Perform the field dielectric test described in

ANSI Standard C37.20.2 at the voltage level

appropriate for the equipment. This test

should check all primary phase-to-ground

and phase-to-phase insulation.