Publication No. 5106227

15

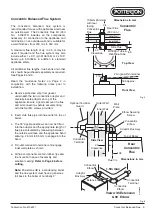

Guidance on Unusual Twin Flue Installations

The following notes offer guidance regarding the

relationship between the maximum flue length and the

number of bends allowed in a twin flue system.

In order to simplify the calculation, the following three

factors are used:-

1. Maximum System Factor

A figure of 100 is used and represents the maximum

resistance that can be applied to the appliance before

there is a notable reduction in its heat output.

2. Fittings Factor

This figure is calculated and represents the total

resistance of all the flue / air fittings in the proposed

system. e.g. bends, terminals and essential pipes such

as those rising from the boiler.

3. Pipe Factor

This figure is calculated and represents the remaining

resistance left for the flue / air pipe lengths in the

proposed system after subtracting (2) from (1).

Note:

Any flue and air pipe combination between the

minimum and maximum lengths may be used in

conjunction with any of the listed fittings, provided that

the Maximum System Factor of 100 is not exceeded.

Table of Flue Resistance Factors :

Component

factor

Mini Terminal (500 mm)

(each)

5.0

Pitched Roof Terminal

7.0

Vertical Terminal (inc. twin pipe adaptor)

6.6

60 mm Air / Flue Pipe - 0.25 m (each)

1.2

60 mm Air / Flue Pipe - 0.5 m (each)

2.1

60 mm Air / Flue Pipe - 1.0 m (each)

3.8

60 mm Air / Flue Pipe - 1.5 m (each)

5.5

60 mm Air / Flue Pipe - 2.0 m (each)

7.2

60 mm Air / Flue Pipe - 3.0 m (each)

10.6

Bend - 92°

4.0

Bend - 135° (45° Bend)

3.4

Bend - 150° (30° Bend)

2.6

Bend - 165° (15° Bend)

1.4

Note:

The above component factors are to be

cumulatively subtracted from the total system factor

of

100

(See Below)

.

Ensure that both

flue and air

pipes are counted.

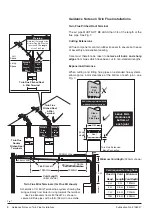

Worked Example

To calculate the maximum allowable air/flue pipe length

for the system shown in Fig. 21.

1. Establish the terminals, bends and essential

pipework (e.g. that rising from top of boiler) and add

the resistance factors obtained from the table above.

4 off 92° Bends

=

16.0 (4 x 4)

2 off 135° Bends

=

6.8 (2 x 3.4)

2 off Mini Terminals

=

10.0 (2 x 5)

Add: Essential Pipework -

2 off 1.5 m Air/Flue Pipes

=

11.0 (2 x 5.5)

Fittings Factor

=

43.8

2. Subtract this Fittings Factor from 100

i.e 100 - 43.8 = Pipe Factor =

56.2

3. Divide this Pipe Factor by the resistance factors

appropriate for the flue being designed.

e.g. 3 off 1 m Air/Flue Pipes =

11.4

6 off 2 m Air/Flue Pipes =

43.2

Total =

54.6

4. Compare this total of to the available Pipe Factor:

54.6

£

56.2 so this system is acceptable.

MAX0039B

Flue

Air

2 135˚

Bends

Factor

2 x 3.4 = 6.8

Factor

4 x 4 = 16.0

Factor

2 x 5.5 = 11.0

2 1.5m Pipes

above boiler

4 92˚

Bends

2 Mini

Terminal

Factor

2 x 5 = 10.0

Fig. 21

Guidance on Unusual Twin Flue Installations