Publication No. 5106227

6

Flue Air

Flue Air

Twin Flue

Pitched Roof

& Mini

Terminal

Example

Flue

Length

4m

Example

Air

Length

3m

Example

Flue

Length

4m

Flue Air

Loft

Space

Living

Space

Warning

Note that the length of the

Air Inlet Pipe MUST not be

less than

0.75 x length

of the Flue Pipe

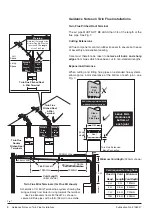

Twin Flue Pitched Roof

& Mini Terminal

Example

Air

Length

2m

50mm

depth

Twin Flue Extension/

Bend Connection

Clean

Cut

Flue Pipe

Do Not Damage Internal Seals

with badly cut extensions

MAX0037A

Twin Flue

Double

Pitched Roof

Terminals

Badly

Cut

Flue Pipe

2˚ Angle

300mm max.

25mm min.

Void required for long flues

Flue Kit

Reqd.

5m

5m

7m

10m

Void

Length

3m

3.5m

5.5m

8.5m

Minimum

Void Depth

180mm

250mm

320mm

425mm

Minimum Void Depth

(320mm shown)

Twin Flue Mini Terminals (7m Flue Kit shown)

Ø60

1.5m

Schematic of 7m Mini Terminal flue system showing flue

rising vertically from boiler & rising towards the terminal.

Use Flue Brackets from kit 5106257 as shown to

secure Air/Flue pipes with a fall of 35mm in one metre.

1950mm

1950mm

Flue Brackets

Void Length

(5.5m shown)

Seal

Leave 5mm

clearance at

bottom of

each joint

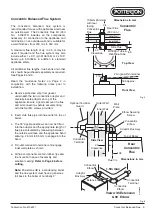

Guidance Notes on Twin Flue Installations

Twin Flue Pitched Roof Terminal

The air pipe MUST NOT BE LESS than 3/4 of the length of the

flue pipe. See Fig. 7.

Cutting Extensions

All flue components contain rubber lip seals to ensure both ease

of assembly and excellent sealing.

Care must therefore be taken to

remove all burrs and sharp

edges

from pipes which have been cut to non-standard lengths.

Expansion Allowance

When cutting and fitting flue pipes on extended flue systems,

allow approx. 5 mm clearance at the bottom of each joint - see

Fig. 7.

Fig. 7

Guidance Notes on Twin Flue Installations