Page 27

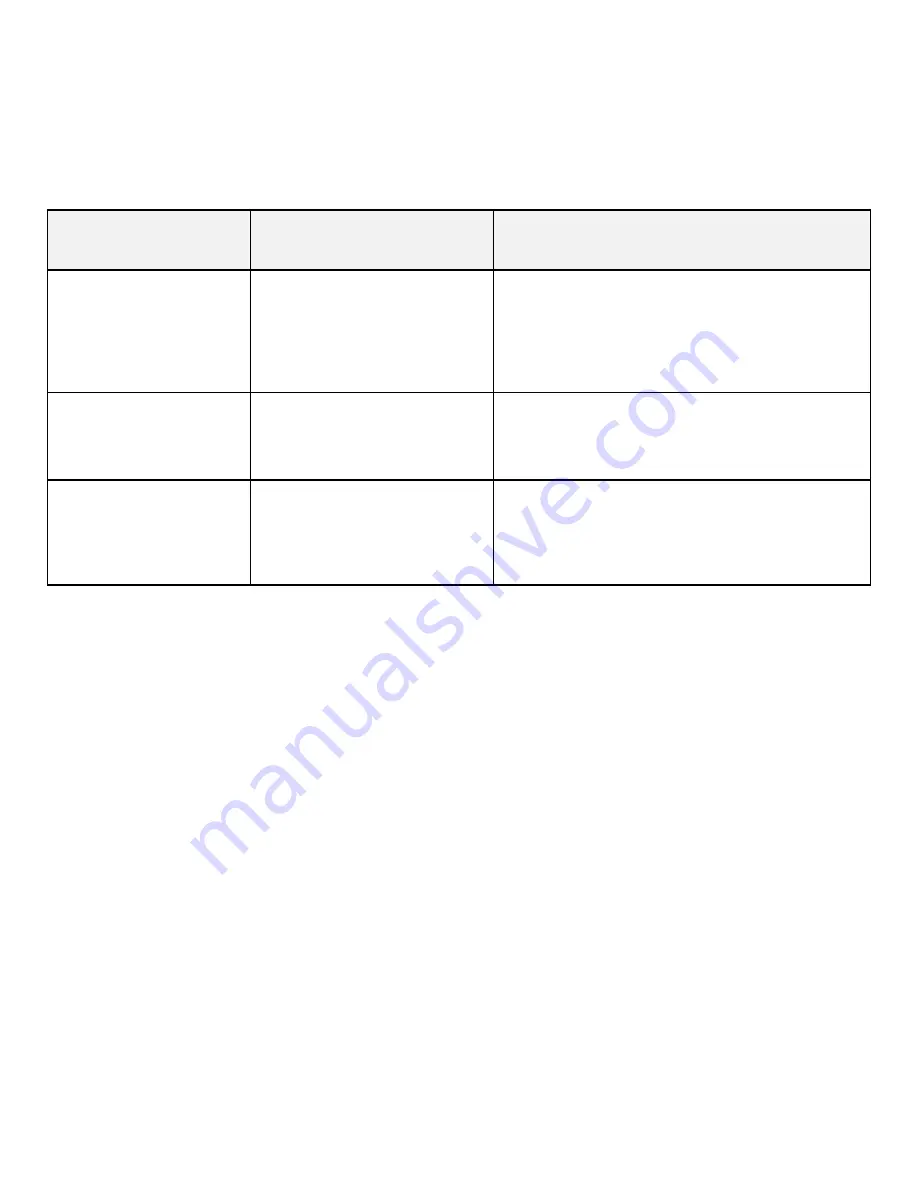

PROBLEM

CAUSE

REMEDY

5.

Unit does not stop at the

proper elevation above

floor (in the DOWN

position).

Down limit switch not adjusted

properly.

Refer to installation instruction No. 15, Figure O.

Proper down limit switch adjustment sets load bar to

the level position. If load bar is not level after

actuating both down limit switches, one or both down

limit switches require adjustment.

6.

Motor overload relay in

Mat Mover

®

control panel

keeps tripping.

Incorrect voltage.

Wire not terminated properly, or

broken.

Contact the electrician or consult the factory.

7.

Pulleys at load bar are

squeaking.

Pulleys require lubrication.

Contact your

Porter

dealer. The load bar will need to

be supported or lowered to the floor, pulley housings

disassembled and sheave to be lubricated via the

grease fitting.

Summary of Contents for 91101-100

Page 4: ......

Page 18: ...Page 14 FIGURE J POWER SOURCE ...

Page 19: ...Page 15 FIGURE K BEFORE ...