Page 16

EMHART TEKNOLOGIES

• 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 •

www.emhart.com

Note:

Numbers in

bold type

refer to call out numbers in illustration.

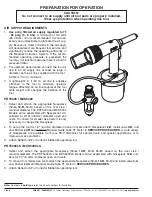

PROCEDURE

1. Loosen Fill Screw

10

.

2. Place the tool upside down in a soft jawed vise. Grip the tool gently on the aluminum casting in the middle

of the tool handle grip area.

3. Remove Clamp Screws

37

and

38

, Clamp Nuts

23

, Right Clamp

42

and Left Clamp

43

.

4. Remove Intensifier Chamber

45

, together with Intensifier Chamber Sleeve

46

. Take care not to loosen

O-ring

8

when removing these parts. Remove O-ring

8

.

5. Slowly withdraw the Intensifier Assembly

29

by pulling up on the air piston.

6. If Fill Screw

10

and Fill Screw Washer

4

have been removed during dismantling reinstall these before

proceeding and tighten hand tight.

7. Remove Nose Housing

44

.

8. Pull out on the Pulling Head Adaptor

28

(or push on the rear of the Hydraulic Piston Rod

26

) to ensure that

the Pulling Head Assembly (Hydraulic Piston) is fully forward.

9. Very slowly fill Ram Sleeve

32

with hydraulic fluid to the bottom of the chamfer. Take care to prevent

aeration of the hydraulic fluid.

10. Position Ram Assembly

29

over Ram Sleeve

32

and tilt slightly to immerse one edge of Ram Seal

40

into

the fluid, then straighten to fully immerse the seal without entrapping air. Push the Ram Assembly in as far

as it will go. The Hydraulic Piston Rod

28

will move rearward.

11. Remove Ram Assembly

29

and repeat steps 8, 9 and 10 above.

12. Remove the tool from the vise and stand it on the Air Piston on a flat surface.

13. Allow a few seconds for any entrapped air to rise in the tool before proceeding.

14. Place a spacer approximately 6mm (1/4 inch) thick between the Air Piston and the Handle

31

then slightly

loosen the Fill Screw

10

and slowly push down on the tool Handle expelling excess hydraulic fluid and

entrapped air from the Fill Screw hole. Continue pushing down until the Handle rests on the spacer.

15. Tighten Fill Screw

10

to torque specifications in Table 1, wipe Handle dry.

16. Lubricate the inside of Intensifier Chamber Sleeve

46

and the outside edge of the Air Piston Seal

30

.

17. Reassemble Intensifier Chamber

45

and Clamps

42

and

43

. Install Clamp Screws

37

and

38

and Clamp

Nuts

23

and tighten to torque specifications in Table 1.

18. Replace Nose Housing

44

and tighten to torque specification in Table 1.

19. Connect air supply to tool and check tool function and stroke length.