OPERATION

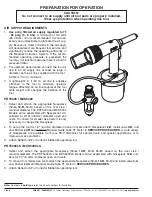

1. Attach Air Line

72

to air supply.

2. If so equipped, turn on the Mandrel Collection System by rotating the Switch/Deflector Ring

67

on the

Mandrel collector until one of the indicators is aligned with the arrow on the top of the tool. There are three

ON

positions so that the air exhaust may be directed away from the operator.

3. Insert a rivet mandrel into the Nosepiece

14

. If the tool is equipped with a Mandrel Collection System (MCS

Models) the rivet will be held in the tool by vacuum.

4. Guide the tool until contact is made between the face of the rivet head and the outer surface of the piece to

be riveted.

5. Squeeze the trigger

13

to set the rivet. Once the rivet is set, release the trigger. If using a PRT5400 or

PRT5400LS be sure to clear the mandrel from the tool by tipping the tool to let the mandrel slide either out

the front or out the back of the tool. If using the MCS5400 or MCS5400LS the mandrel will be automatical-

ly propelled into the mandrel Collector Bottle.

SERVICE PROCEDURES

CHANGING TOOL SET UP FOR DIFFERENT RIVET SIZES

To prevent mandrel jams from occurring and to maximize jaw life it is important to install the correct Nosepiece,

Jaws, Jaw Pusher and Mandrel Guide tube.

For

3/16" (4.8mm)

diameter or smaller rivets use the following parts:

Item

3

Jaws, Part No. PRG540-46

Item

22

Jaw Pusher, Part No. PRT5500-6

Item

71

Mandrel Guide Tube, Part No. PRG540-43

Item

12

Nosepiece - PRN414 for 1/8" (3.2mm) diameter rivets

PRN524 for 5/32" (4.0mm) diameter rivets

PRN614 for 3/16" (4.8mm) diameter rivets

For

1/4" (6.4mm)

diameter rivets use the following parts:

Item

3

Jaws, Part No. PRG540-44

Item

22

Jaw Pusher, Part No, PRT5500-8

Item

12

Nosepiece - PRN811 for 1/4" (6.4mm) diameter rivets

(no Mandrel Guide Tube is required)

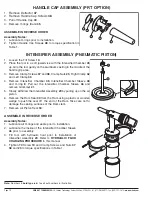

Equipment Needed:

7/16" (11mm) O.E. Wrench

Two adjustable wrenches 1" (26mm) or larger

Soft-jawed vise

Procedure

1. Place the tool in a soft-jawed vise, gripping the tool in the center of the handle.

2. Remove the Nosepiece

12

.

3. Remove the Nose Housing

44

.

4. Remove the Jaw Guide

11

, Jaws

3

and Jaw Pusher

22

.

5. Insert (or remove) the Mandrel Guide Tube

71

into the Jaw Pusher Spring

5

.

6. Install the correct Jaw Pusher

22

.

7. Install the correct Jaws

3

.

8. Re-install the Jaw Guide

11

and tighten to torque specifications in Table 1.

9. Replace the Nose Housing

44

and tighten to torque specifications in Table 1.

10. Install correct Nosepiece

12

and tighten to torque specifications in Table 1.

Caution:

Read the

Operator Instruction Leaflet

before operating the tool.

Note:

Numbers in

bold type

refer to call out numbers in illustration.

EMHART TEKNOLOGIES

• 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 •

www.emhart.com

Page 7