3

2

5

1

Note:

O

il

Supplied

Separ

atel

y

10

9

11

12

PUM

P

CO

VER

7

6

PAR

TS

LIST

ITEM

Q

TY

PAR

T

NUM

BER

DESCRIPTIO

N

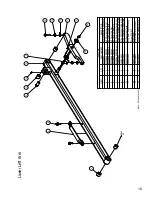

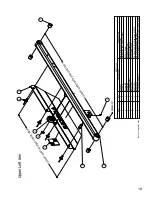

1

1

ACCF

ABPM

P50840

ACC

External

Pump

Br

ack

et

2

1

ACCHYDHO

S530-001-700

ACC

O

uter

Bo

x

Hose

700

3

1

ACCHYDPM

PZEF12/24

RFP

Encl

osed

Pack

12V/24V

4

10.000

g

CO

NO

T/0014

500g

Petr

ol

eum

Jel

ly

5

2

FA

SBL/1029

M

10

x

60

Hex

Head

Set

Scr

ew

6

2

FA

SNT/1001

M

10

Nyloc Nut

7

4

FA

SW

A/1001

M

10

Pl

ai

n

W

asher

Form

A

9

1

CO

NL

B/0020

AF26

Al

u

Foil

w/on

Label

s

Seri

al

No

. (P

ack 350)

10

1

CO

NL

B/0002

WL

28

LABEL

LEGEND

TESTED

(

PACK

350)

11

1

CO

NL

B/0003

Thi

s

W

ay

Up

&

PLS

Blue

Sti

ck

er

12

1

ACC26469

Vi

nyl

R

ound PLS

Label

Note:

-

Fi

xi

ngs

ma

y

vary

External

Encl

osed

Pack

Horiz

ontal

P

osi

tion

30

Summary of Contents for Access ACC-1150

Page 7: ...1 1 5 Heath Safety Scooters General ...

Page 23: ...7 7 7 Floor Height Adjustment Installation 7 INSTALLATION 7 6 Floor Height Adjustment ...

Page 25: ...7 7 9 Weight Test Installation 7 INSTALLATION 7 8 Weight Test Dynamic Dynamic ...

Page 30: ...Thread Size Tightening Torque Nm Hydraulic Fitting BSP 1 8 17 0 1 4 34 0 3 8 47 0 ...

Page 31: ...8 8 1 Standard Operating Procedure Operation 8 OPERATION 8 1 Standard Operating Procedure ...

Page 32: ...8 8 2 Manual Override Procedure Operation 8 OPERATION 8 2 Manual Override Procedure ...

Page 35: ...10 10 2 Loler Service Maintenance ...

Page 44: ...13 13 1 Wiring Diagram Power Pack Diagrams 13 DIAGRAMS 13 1 Wiring Diagram Power Pack ...

Page 46: ...13 13 3 Hydraulic Diagram Diagrams 13 DIAGRAMS 13 3 Hydraulic Diagram ...

Page 82: ...15 Notes ...

Page 83: ...15 Notes ...