10

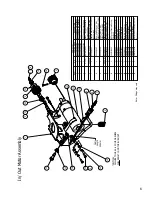

10.7 31 Point Check

Service &

Maintenance

LOLER / SERVICE Repair Check List

Lift no:

Vehicle Reg:

Engineer’s Name:

Date:

Customer Details:

Address, Contact:

Tel. Number:

Poor

Ok

Good

1

Ramp stop (roll-off) operation/condition

2

Condition of ramp stop cylinder (corrosion, leaks, loose caps)

3

Bridging plate operation/condition

4

Carriage lock and rocker(s) working correctly

5

Platform stability

6

Platform extension operation (stops tight)

7

Platform stowage set correctly

8

Handrail and side guard operation/condition

9

Cleating and wearstrip condition

10 All set pins secure/ Grub screws tight

11 All fasteners tight

12 In/Out Motor operation/condition/ check top cog

13 Condition of all bearings and camfollowers/ grease x 4

14 Umbilical hose condition

15 Check lift isolator (cab or door switch)

16 Condition of lifting cylinders (corrosion, leaks, loose caps)

17 Up/Down hydraulic pump operation/condition (relief valve) with SWL on lift

18 Hand pump operation/condition/ check tightness

19 All hoses in good condition/ arm hose/ cylinder hoses and platform pipe & hose.

20 Hydraulic fittings in good condition/ ports on power pack tight

21 Wiring loom condition (crimps, fuse holder, earth wires, etc)

22 Box lock operation/condition

23 Condition of box tracks (not bent or indented)

24 Top and bottom sheets secure

25 Box brushes present and secure

26 Condition of stowage box and fitting brackets

27 Lift correctly lubricated/ cam followers / extension/ switches and cam and cranks.

28 If powermatic, in/out operation & switches set correctly

29 Speed of operation acceptable

30 Handset condition

31 Labels and operating instructions

Engineers Comments

10.7 31 Point Check

Summary of Contents for Access ACC-1150

Page 7: ...1 1 5 Heath Safety Scooters General ...

Page 23: ...7 7 7 Floor Height Adjustment Installation 7 INSTALLATION 7 6 Floor Height Adjustment ...

Page 25: ...7 7 9 Weight Test Installation 7 INSTALLATION 7 8 Weight Test Dynamic Dynamic ...

Page 30: ...Thread Size Tightening Torque Nm Hydraulic Fitting BSP 1 8 17 0 1 4 34 0 3 8 47 0 ...

Page 31: ...8 8 1 Standard Operating Procedure Operation 8 OPERATION 8 1 Standard Operating Procedure ...

Page 32: ...8 8 2 Manual Override Procedure Operation 8 OPERATION 8 2 Manual Override Procedure ...

Page 35: ...10 10 2 Loler Service Maintenance ...

Page 44: ...13 13 1 Wiring Diagram Power Pack Diagrams 13 DIAGRAMS 13 1 Wiring Diagram Power Pack ...

Page 46: ...13 13 3 Hydraulic Diagram Diagrams 13 DIAGRAMS 13 3 Hydraulic Diagram ...

Page 82: ...15 Notes ...

Page 83: ...15 Notes ...