260

Precautions

6.1 Precautions

1) If the power shuts down and stays OFF for an extended time, an internal problem has probably occurred (failing part,

etc.).

Turn OFF the main power switch on the Plasma Display then wait one to two minutes then try turning the power ON

again.

If the power goes OFF again, the display needs to be serviced.

If the display operates normally, the power reset has cleared the issue.

2) When an image (still image, telop or subtitle, etc.) is shown on the screen for a long period, there is a possibility that

the image could burn in. This should be managed by making changes in the imaging software, display method,

system configuration etc.

3) The following kinds of input signals could cause inferior image quality (when a PDA-5003/PDA-5004 card is installed).

• Video signal that has been dubbed (copied) repeatedly

• Copyright-protected signals

• Scrambled cable TV signals

• Signals with a sync signal and video signal that are extremely out of phase

4) The fan starts operating when the surrounding temperature is greater than 32 °C (the fan rpm becomes faster as the

temperature increases, this is normal).

5) Screen-saver function (still image detection)

When an image having little motion such as a photograph or PC screen is displayed continuously, the image may

appear dimmer. To protect the plasma panel, the screen-saver function detects images with little or no motion and

automatically adjusts the brightness. This action is not an indication that the display is failing.

Time until the screen-saver function operates:

• Normal-operation mode/menu mode: Approximate three minutes after the power is turned ON or after the input is

switched

7

Self-diagnosis Function

When there is an operating or connection error, a message appears on the screen.

After reading the contents of the error message, check the condition of the unit.

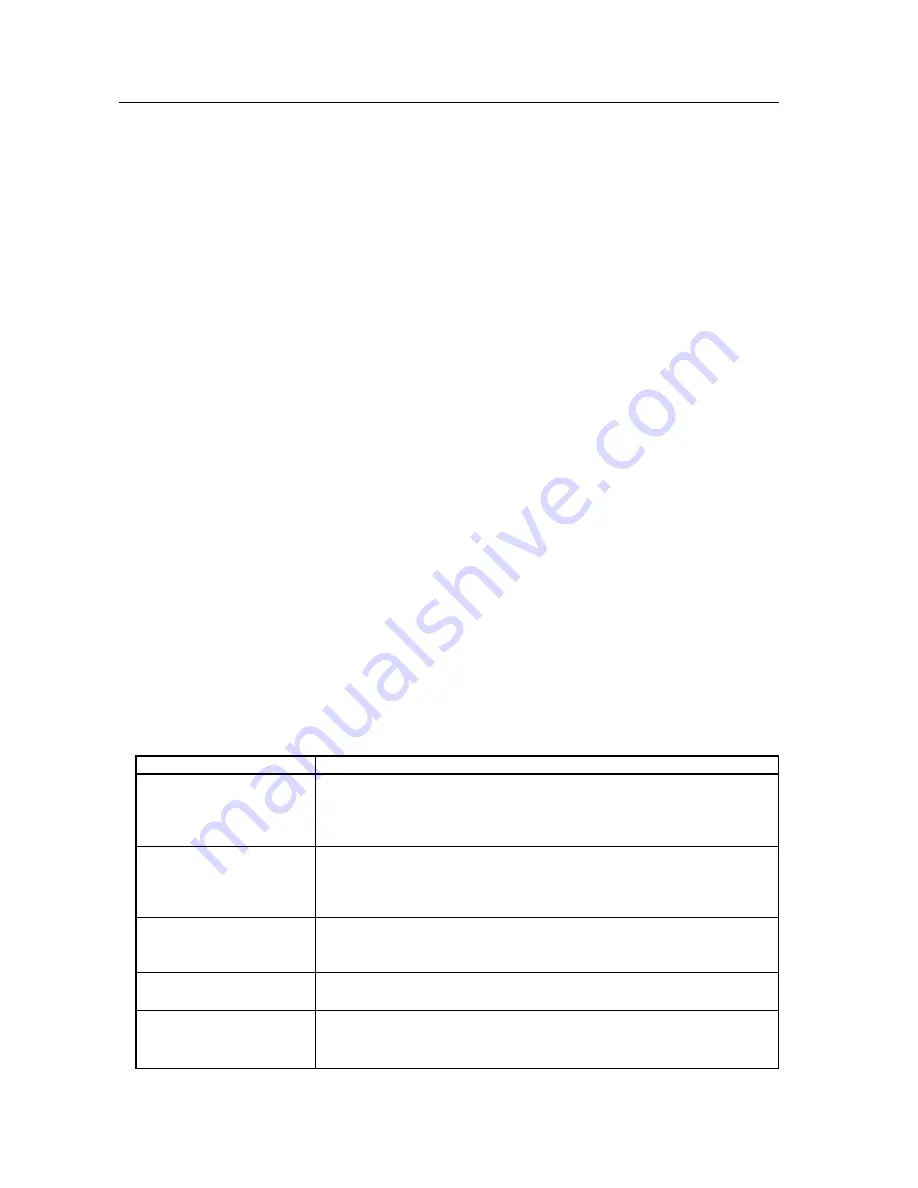

Error Message

CAUTION

OUT OF RANGE

UNSUPPORTED SIGNAL

SIGNAL NG

WARNING

THERMAL ALERT

SHUT DOWN

WARNING

FAN FAILURE

SHUT DOWN

ERROR

INVALID KEY ENTRY

SHUT DOWN

Remedy

¶

The current signal input is not supported by the unit. Check the table of supported

input signals on pg. 146 to 153 and change the output signal setting.

¶

Turn OFF the main power.

¶

Check whether the surrounding temperature is high.

¶

If the cooling vents on the display are blocked, remove the obstacles blocking the

vents.

¶

There is a problem with the fan. Immediately turn OFF the power and contact a

Pioneer service center or dealer.

¶

An invalid operation was attempted. Check the input signals, connections and

settings.

¶

Turn the main power OFF, wait one or two minutes and turn the power ON again. If

the problem still persists, remove the power plug from the outlet and contact a

Pioneer service center or dealer.