Go to cover page

202P7 CRT

7

Electrical Instructions

adjustment for Smart mode color once it finished the 6500

°

K

from 7.2.1 to 7.5.2 .CAA re-adjusts the 5500

°

K & 9300

°

K

then adjusts 4000

°

K, 4600

°

K and 8000

°

K, figures out the

necessary 2 groups (one for G-gain, one for B-gain) of 1

constant and 3 coefficients data by these adjustments and

writes it into EEprom via MCU of the monitor under tested,

the address A0 page 0xF0 to 0xF7 store the G-gain data,

0xF8 to 0xFF store the B-gain data. The MCU of monitor will

perform the SmartMode color by these data.

8.

Adjustment of the picture geometry

8.1

EEprom data has to be preset data according to software

approval sheet.Sheet 139, sheet 140. Pre-set data please

refer: TIMING TABLE 1 to 36

Note: The EEprom should be loaded beforehand with average

values of mode preset data and mode preset selection bytes.

This preload data should be collected by EPE from product

batch by batch to keep the entire image of all preload modes

display inside the bezel with the a specification of H-width:

392mm

±

10 mm and V-size: 294mm

±

10mm.

8.1.1

Preload the default DAC value into following listed items-

Item

DAC Value

Remark

FOCUS H / V

0 / 200

Default

VLINBAL

85

Default

USER H-Range

64

Specified

RASTER H / V

160 / NU

Default

LIN H / V

* / 223

Default

SUB

Å

(ZOOM -Range)

64

Specified

V OFFSET / GAIN

150 / 200

Specified

D convergence

0

Default

NS Purity

127

Specified

CORNER TOP/BOTTOM

105 / 95

Default

BAIS LIMIT

153

Specified

Remark: Default - EPE has to correct these values batch by

batch to achieve best product FOS.

Specified - These values should be kept no change for the

production, Dev has the Responsibility to check and modify

with the proper values.

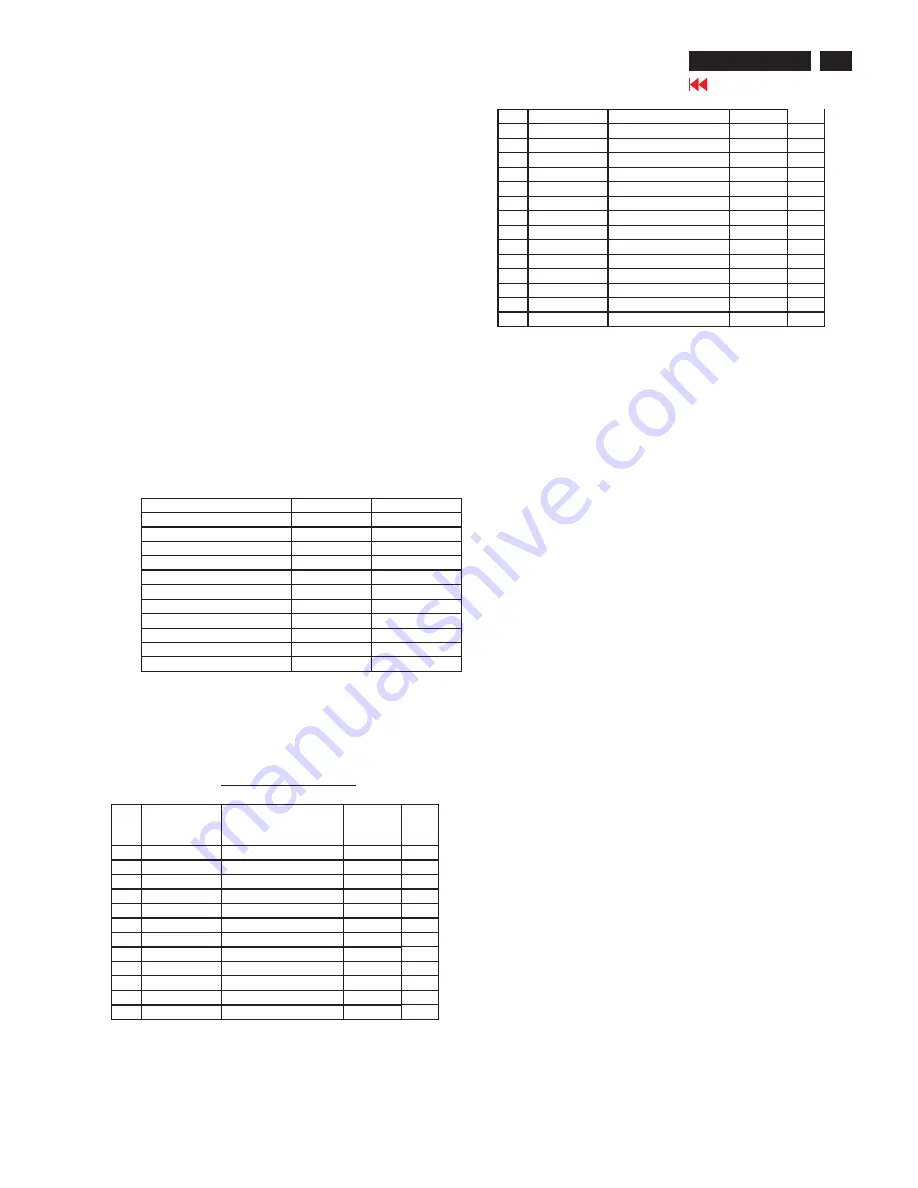

H-linearity default setting

Freq.

Range

KHz

Resolution

@Hz

DAC

Value

1

~33.0

720*400 @ 70.0

85

2

33.0~36.0

800*600 @ 35.2

100

3

36.0~42.0

640*480 @ 75.0

105

4

42.0~45.0

640*480 @ 85.0

120

5

45.0~47.5

800*600 @ 75.0

120

6

47.5~49.0

1024*768 @ 60.0

125

7

49.0~52.0

832*624 @ 74.5

125

8

52.0~55.0

800*600 @ 85.0

135

9

55.0~58.5

1024*768 @ 70.0

135

10

58.5~61.5

1024*768 @ 75.0

140

11

61.5~65.0

1280*1024 @ 60.0

140

12

65.0~70.0

1024*768 @ 85.0

150

13

70.0~73.0

1125*900 @ 76.0

155

14

73.0~76.0

1600*1200 @ 60.0

155

15

76.0~80.6

1152*864 @ 85.0

165

16

80.6~82.5

1600*1200 @ 65.0

165

17

82.5~84.8

1792*1344 @ 60.0

165

18

84.8~88.5

1600*1200 @ 70.0

165

19

88.8~92.5

1280*1024 @ 85.0

175

20

92.5~98.0

1600*1200 @ 75.0

175

21

98.0~102.0

1600*1200 @ 80.0

175

22

102.0~110.0

1792*1344 @ 75.0

175

23

110.0~113.5

1920*1440 @ 75.0

180

24

113.5~122.0

2048*1536 @75.0

170

25

122.0~126.5

1856*1392 @ 85.0

185

26

126.5~

1920*1440 @ 85.0

185

27

130

2048*[email protected]

185

8.2

Alignment of horizontal and vertical geometry.

8.2.0

Enable the MAGNETIC function in the MODEL SELEC (

factory mode OSD).

8.2.1

Apply the timing mode 2048x1536 120kHz 75Hz (timing

table 35), pattern FIG.1 to FIG.4 to set under tested.

Correct the test image to display in parallel with front top

plastic bezel by adjusting the Rotate item in OSD Adjust

shape. Repeatedly do the adjustments from 8.2.2 to

8.2.13 to correct the geometry of this mode and fix the

position of horizontal raster on display screen.

8.2.2

Adjust Raster H (in factory mode) to make the horizontal

raster symmetrical display at center of the screen.

8.2.3

Adjust the H-Width to 392mm.

8.2.4

Adjust the H-linearity to get optimum horizontal deflection

linearity display block to block.

8.2.5

Adjust the H-Phase to center position.

8.2.6

Adjust the side curve - Pincushion & Balance to get

optimum right vertical lines.

8.2.7

Adjust the side angles - Trapezoid & Parallelogram to

get optimum right vertical lines.

8.2.8

Adjust the Corner Top & Bottom to get optimum right

vertical lines.

8.2.9

Adjust the Vertical size to 294 mm.

8.2.10

Adjust the vertical linearity to get optimum vertical

deflection linearity display block to block.

8.2.11

just the Vertical phase to center.

8.2.12

epeatedly do the adjustments from 8.2.3 to 8.2.11

to optimize the geometry performances and meet the

specification (sheet 161) request.

8.2.13

Exit OSD and auto saves the alignment data.

8.2.14

Repeat the procedure of 8.2.2 - 8.2.13 to all inspection (

preset) & alignment modes listed in the following Factory

timing modes table (total 11 modes) until all have been

adjusted completely.

Summary of Contents for 202P70/00

Page 37: ...37 202P7 CRT Go to cover page Wiring Diagram ...

Page 41: ...41 202P7 CRT Go to cover page Main Board C B A 1 ...

Page 42: ...42 Main Board C B A 2 Go to cover page 202P7 CRT ...

Page 44: ...44 Go to cover page Video Board C B A 1 202P7 CRT ...

Page 45: ...45 202P7 CRT Go to cover page Video Board C B A 2 ...

Page 47: ...47 202P7 CRT Go to cover page TERMINAL Board C B A 1 ...

Page 48: ...48 TERMINAL Board C B A 2 Go to cover page 202P7 CRT ...

Page 50: ...50 Driver Board C B A Go to cover page 202P7 CRT ...

Page 51: ...51 202P7 CRT Go to cover page KEY CONTROL Schematic Diagram C B A ...

Page 52: ...52 MHR Schematic Diagram C B A Go to cover page 202P7 CRT ...