122

123

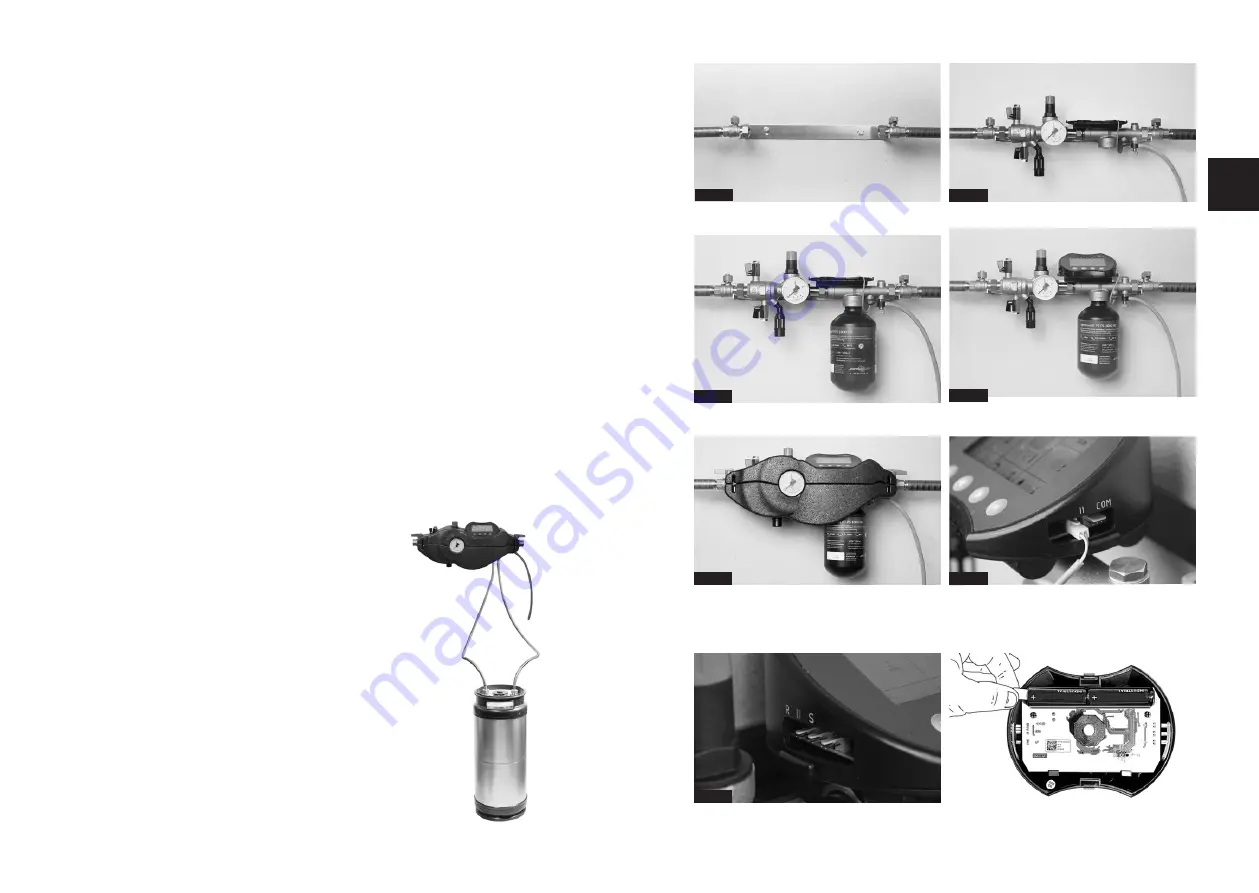

Fig. 1

Fig. 2

Fig. 4

Connections on the left on the display:

signal cable (R), conductance sensor (II), pulse cable (S)

Connections on the right: conductance sensor (II), prepa-

ration for bidirectional communication (COM)

Fig. 3

Fig. 5

Fig. 6

Installation of digital heating filling stations PT-DB(P)

Observe the flow direction (arrow on filling station)

1. Fasten the holding bracket

⑤

to the wall with the screw set provided (fig.1)

2. Mount pressure gauge and opposite blanking plug on system separator

⑥

3. Screw the ball valves

②

on (fig.2)

4.

Screw in the PT-PS1000 or PT-PS5000FD

permasoft

①

from underneath (fig. 3),

alternatively connect the PS-AD28000 adapter with the flexible connection hoses

for PT-PS28000E to the fitting.

5. Push the electronics housing

③

on (fig. 4), for PT-DB first removed the paper flag on the

battery compartment (2x AA battery) (fig. 8)

6. Plug in the conductance sensor (II) on the side of the electronics; possible on both sides

(fig.6, 7)

7. If necessary, plug in the pulse cable (S) and/or signal cable to the relay (R) (fig.7)

8. Connect power supply plug for PT-DBP

9. Push the flushing hose

④

onto the bleed valve

10. Attach the front insulating shells

For the initial filling with the PT-PS18000 or PT-PS18000 Alu

permasoft, or for larger refill volumes with the PT-PS28000E

permasoft for stationary use, these permasoft versions can

be connected via an optional adapter.

Installation of the PS-AD28000 adapter flange

1. To do this, screw the optionally available adapter flange

into the thread underneath the electronics

2. Now connect the two flexible hoses to the PT-PS28000E

demineralisation unit. In doing so, observe the flow

direction on the adapter and permasoft.

Fig. 8

Fig. 7

EN

Summary of Contents for PT-DA-CH5000

Page 72: ...142 143...