Air Supply

The machine requires a clean, dry air supply with a constant pressure of 80 PSI. The

volume of air required is 0.744 SCF/Cycle at 80 PSI.

Note:

This machine is equipped with an electrical air supply and dump valve. Pressing

the E-stop button exhausts compressed air in the machine circuit. Pulling out the

E-stop button and pushing the Start button re-energizes the system.

1.

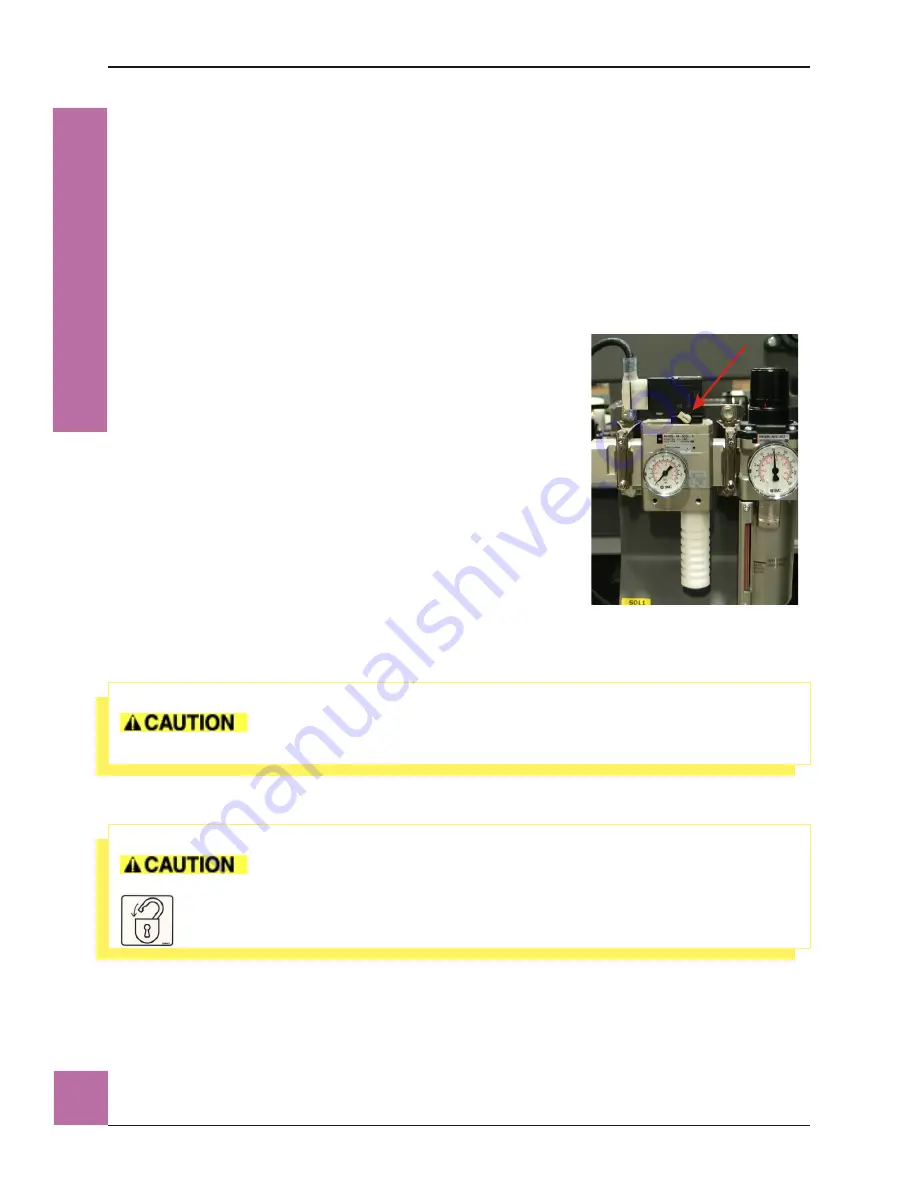

Once air is connected, manually lock air (open) onto machine. Check or

perform a pneumatic integrity test of all hoses,

fittings, and cylinders. Correct any

discrepancies found to leak or discharge air

from pneumatic system.

2.

Use a minimum ¾” NPT air line and connect

plant air to the machine.

Note:

Size the air line to match the inlet line on the air

prep unit.

Final Checks

Perform a motor rotation check of the conveyor motor. If the

motor initially runs in the wrong direction, reverse the polarity.

Recheck the motor.

1.

Verify machine and case/tray set up before attempting to run case/tray.

Before making any adjustments to the machine: Turn off main

power; turn off air supply; follow lock out/tag out procedures.

CE35-T Case Erector

Operations Manual

3/2/2010

M-CE35T-2c Horiz Mag

26

n

oi

t

al

l

at

s

nI

Fig. 16: Manual Air Lock

Button