Microdrive Series Instruction Manual

4201-109 Rev I

51

15

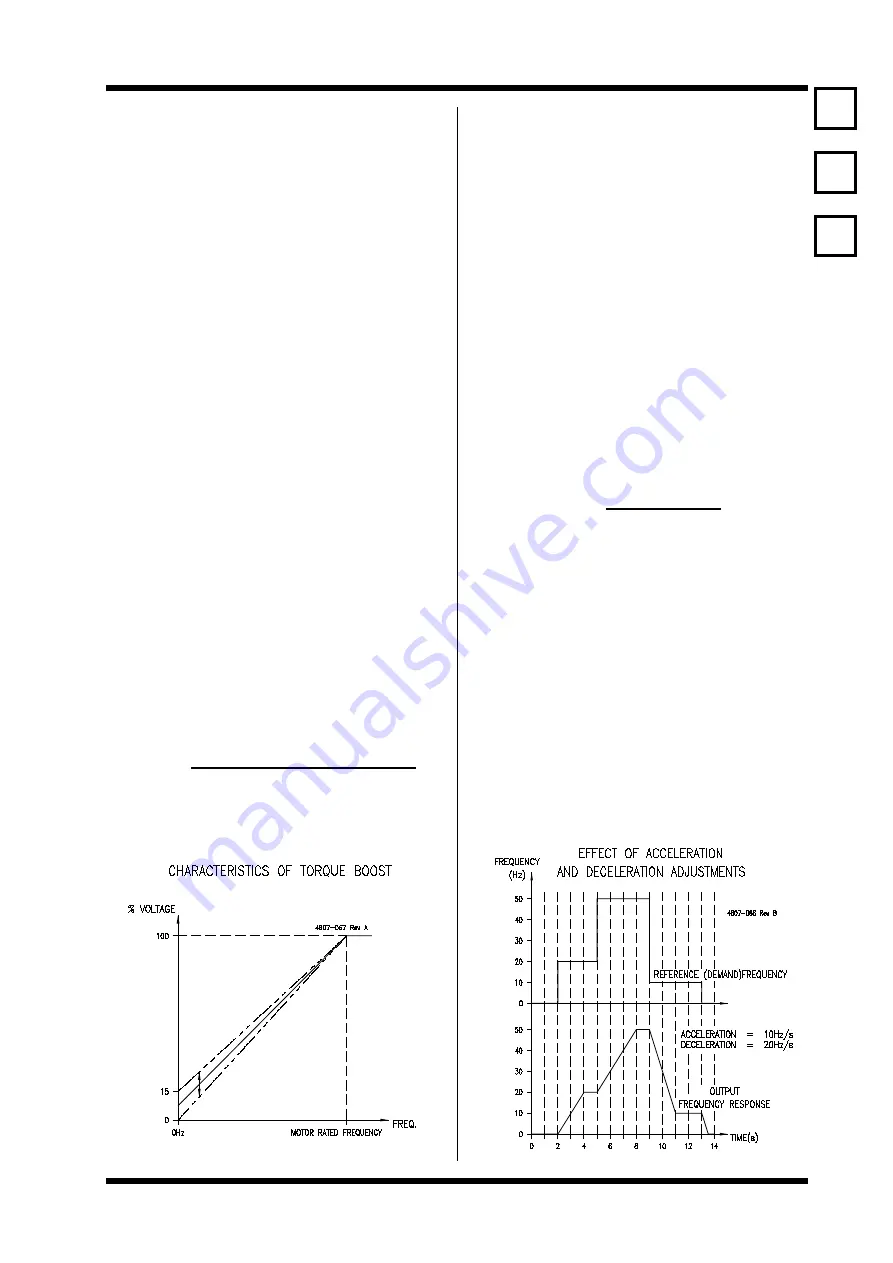

ACCELERATION RATE (NORMAL)

16

DECELERATION RATE (NORMAL)

Screen

15 ACC1=10.0Hz/s

Description

ACCELERATION RATE (NORMAL)

Min/Max

0.02/500

Units

HERTZ/SEC

Screen

16 DEC1=10.0Hz/s

Description

DECELERATION RATE (NORMAL)

Min/Max

0.02/500

Units

HERTZ/SEC

FUNCTION

Control the rate of acceleration and

deceleration of the motor (See also Screens

39 - 41).

SETTING UP Estimate the desired acceleration

(deceleration) time to (from) the proposed

operating speed. Knowing the speed and

time, calculate the acceleration

(deceleration) rates:

Rate = proposed speed (Hz)

accel (decel) time (s)

Use the slowest settings acceptable for your

application. An acceleration rate which is too

fast may cause the Microdrive to overload

(status ILT) and automatically override your

setting with a slower one. A deceleration

rate which is too fast can cause the motor to

regenerate (status VLT) into the Microdrive

and automatically override your setting with

a slower one.

Being realistic with these settings generally

leads to a more successful commissioning.

Where fast accelerations/decelerations are

called for, it is often best to use slower

settings initially, until all other operations are

proven (also refer Screens 18, 19, 20).

Freewheel to stop (instead of controlled

deceleration) can be achieved by setting the

stop mode (Screen 61) to spin.

14

TORQUE BOOST

Screen

14 BOOST = 0.0%

Description

TORQUE BOOST VOLTAGE AT ZERO

SPEED

Min/Max

0.0/15.0

Units

%V(MOTOR)

FUNCTION

To provide a compensating voltage to

improve low speed torque.

SETTING UP Torque boost has two modes configured in

Screen 77. With autoboost set to [Y]es (the

default condition) the drive automatically

adjusts the boost level (up to the set level)

in accordance with load variations.

When set correctly the Microdrive should be

capable of delivering rated torque at rated

current under stall conditions (shaft

stationary).

With autoboost set to [N]o the boost voltage

follows the profile shown in the following

figure.

Some experimentation is usually required to

find the optimal level. Use only as much

boost as is required to reliably start your

motor. If you use too much boost the motor

may draw excessive current, possibly

overloading the Microdrive and the motor.

When several motors are run from the same

inverter with differing loads, autoboost

should be set to [N]o.

Pump and fan applications usually require

no torque boost.

For either boost mode, a first estimate of the

boost required is equal to the percent slip of

the motor:

Percent slip

of motor =

100 x (synchronous speed - rated speed)

synchronous speed

It is possible to use much higher levels of

boost in autoboost mode (up to 2x percent

slip of motor) and achieve better starting

torque. Refer also Screen 77.

14

15

16

Summary of Contents for D3-2.5

Page 2: ...Microdrive Series Instruction Manual 4201 109 Rev I 4201 003 Rev A Page 2 of 12...

Page 6: ...Microdrive Series Instruction Manual 4201 109 Rev I 4201 003 Rev A Page 6 of 12...

Page 12: ...Microdrive Series Instruction Manual 4201 109 Rev I 4201 003 Rev A Page 12 of 12...

Page 55: ...Microdrive Series Instruction Manual 4201 109 Rev I 55...

Page 74: ...Microdrive Series Instruction Manual 4201 109 Rev I 74...

Page 75: ...Microdrive Series Instruction Manual 4201 109 Rev I 75...

Page 76: ...Microdrive Series Instruction Manual 4201 109 Rev I 76...

Page 77: ...Microdrive Series Instruction Manual 4201 109 Rev I 77...

Page 78: ...Microdrive Series Instruction Manual 4201 109 Rev I 78...

Page 79: ...Microdrive Series Instruction Manual 4201 109 Rev I 79...

Page 80: ...Microdrive Series Instruction Manual 4201 109 Rev I 80...

Page 81: ...Microdrive Series Instruction Manual 4201 109 Rev I 81...

Page 82: ...Microdrive Series Instruction Manual 4201 109 Rev I 82...

Page 83: ...Microdrive Series Instruction Manual 4201 109 Rev I 83...

Page 112: ...Microdrive Series Instruction Manual 4201 109 Rev I 112...

Page 113: ...Microdrive Series Instruction Manual 4201 109 Rev I 113...