Bulletin TI-NITROFLOW TG2-G

Installation, Operation and Maintenance Manual

TI-NITROFLOWTG2

www.labgasgenerators.com

12

1-800-343-4048

1

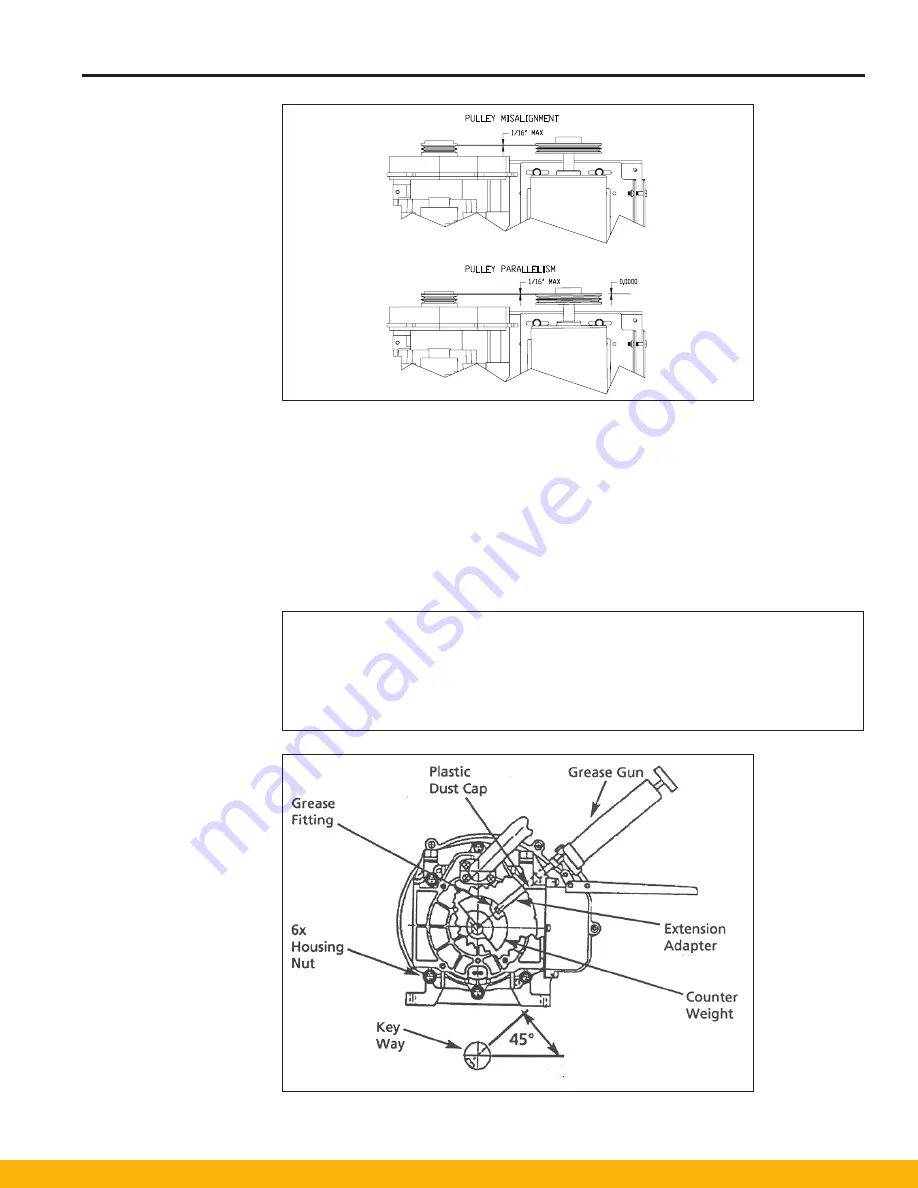

Remove the plastic dust cap from the pump (see Figure 16).

2

Rotate the compressor pulley until the grease fitting is visible in the dust cap hole.

3

Using a grease gun extension adapter to engage the grease fitting, supply the proper amount

of grease according to the grease delivery Table 1, Figure 16.

Note: Pump grease gun before feeding to eliminate air from the needle adapter. Each pump

equals 0.65 grams of grease. The volume of grease is less after the 2nd pump since some

grease remains in the extension adapter.

4

Replace the plastic dust cap.

Figure 15, belt diagram

Grease Orbital

Scroll Compressor

Bearings

Table 1 - Grease Delivery

SLAE03E

Bearing

1st Pump

2nd Pump

Orbit Scroll Bearing

5 times

4 times

Pin Crank Bearing

4 times

4 times

(Orbit Scroll side)

Figure 16 Grease and Orbit Scroll Bearing