Tools Materials Required for Servicing

HGF Service Manual

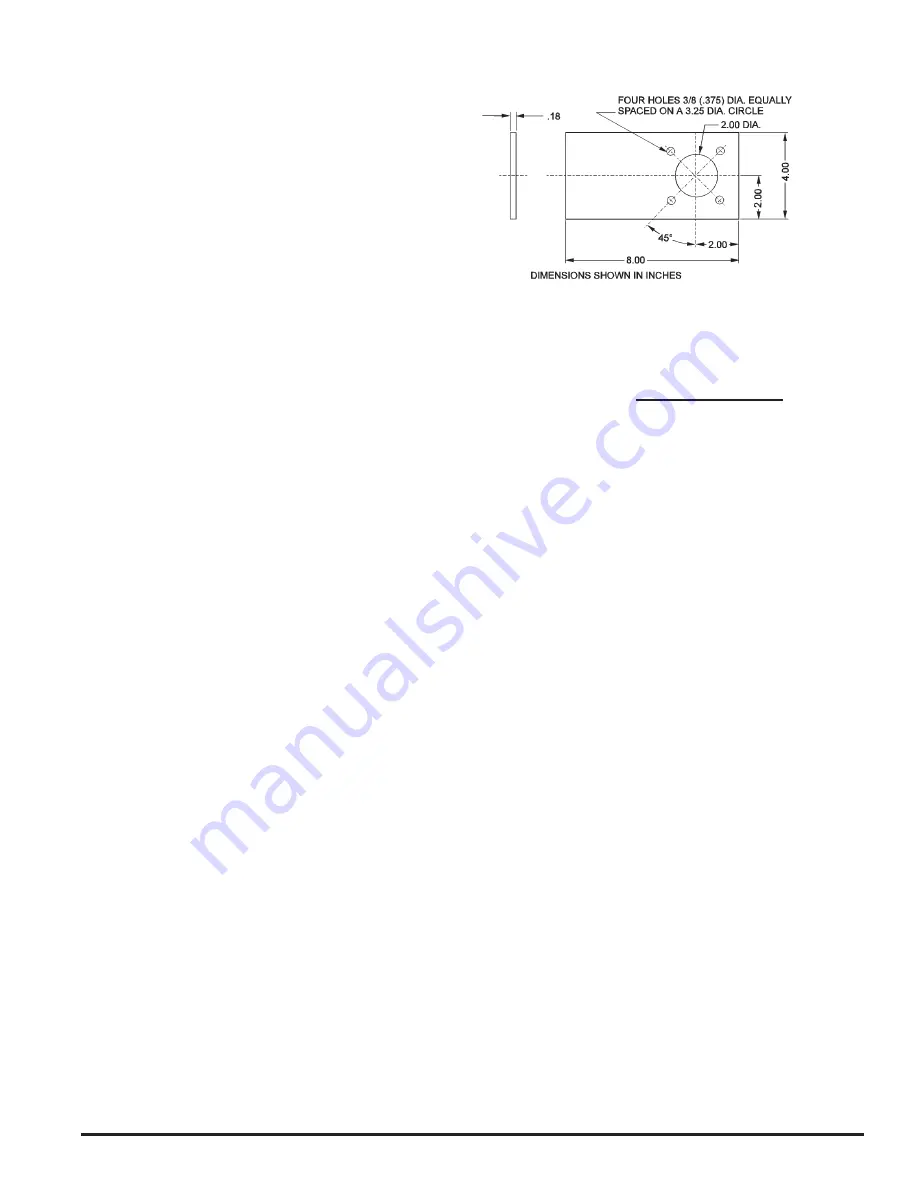

HGF service ass'y fixture (See Figure 1)

Clean, petroleum-based solvent

Vise

Pliers

Screw driver

Blunt ended punch

6 pieces of .007 inch (.18 mm) shim stock, approximately

.5 inch (13 mm) wide x 1.5 inch (38 mm) long.

External retaining ring pliers

Tape, plastic electrical

Breaker bar

Sockets: 1/2, 7/8 inch

3/32 inch Allen wrench socket

T-30 Torq socket

Slot type screw driver socket

5/16-24 UNF hex nut (4) required

3/4 inch (19 mm) to 7/8 inch (22 mm) bearing puller

Clean grease

Light weight oil

Torque wrenches: 11–13 in. lb. & 25–35 ft.lb. or Newton Meter

Feeler gauge .003 in. (.08 mm) or .005 in. (.13 mm)

(See disassembly procedure #37)

Electrical continuity checking device

Torque Chart

Exploded View

Part Name

Item Number

Torque

Socket Head Cap Screws

18

11-13 in-lbs. (1.24-1.47 N m)

Plug and O-Ring Ass'y

6, 7

8-12 ft-lbs. (11-16 N m)

Plug and O-Ring Ass'y

6A, 7A

25-35 ft-lbs. (34-48 N m)

Hex Nut 5/16-24

1

18-22 ft-lbs. (25-30 N m)

Jam Nut 5/8-18

41

25-30 ft-lbs. (34-41 N m)

Jam Nut 13/16-20 UNEF

41

30-40 ft-lbs. (41-55 N m)

8

HGF Series Service Procedure

CONVERSIONS

INCHES

mm

0.18

0.375

2.0

3.25

4.0

8.0

4.6

9.5

51.0

82.6

101.6

203.2

Figure 1