PAT1M / PAT1.5M OPERATION MANUAL

PAT1M/PAT1.5M: PA22222A01_03

Page: 17 of 36

Dec., 2007

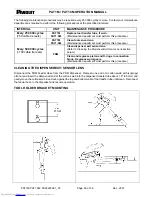

ERROR 3 - Check for low air pressure

Check for low air pressure

Load

Unload

MENU

Buzzer

POSSIBLE CAUSE:

This message will be displayed if the incoming air pressure is too low, or not connected.

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off". Increase the air pressure to 65

PSIG (4,5 bar).

PREVENTION:

To prevent this problem from recurring, verify that the air line is connected, and the air pressure is

between 65 and 85 PSIG (4,5 and 5,8 bar), with a maximum 10 PSI (0,7 bar) drop.

ERROR 4 - Check for high air pressure

Check for high air pressure

Load

Unload

MENU

Buzzer

POSSIBLE CAUSE:

This message will be displayed if the incoming air pressure is too high.

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off". Decrease the air pressure to

below 85 PSIG (5,8 bar).

PREVENTION:

To prevent this problem from recurring, verify that the air pressure is between 65 and 85 PSIG (4,5

and 5,8 bar), with a maximum 10 PSI (0,7 bar) drop.

ERROR 5 - Dispenser jam - check tie loading

Dispenser jam - check tie loading

Load

Unload

Buzzer

Continue

POSSIBLE CAUSE:

This occurs if the dispenser rotary receiver is prevented from advancing (rotating) to the next

position. This may be caused by a jam due to bowed or misaligned cable ties feeding into the rotary receiver, or a jam

due to a backed-up cable tie carrier strip in the carrier strip exit chute.

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off". At this point, check the rotary

receiver and connection block for misaligned or jammed cable ties, and check that the carrier strip scrap chute is

clear. Press the

"Unload"

button to back the cable ties out until the jam and all remaining loose cable ties are

cleared from the rotary receiver. Cut the excess carrier strip and any distorted or damaged cable ties from the cable

tie strip. Close the dispenser cover and perform the normal loading procedure.

PREVENTION:

To prevent this problem from recurring, load the dispenser with care to prevent misaligned cable ties

in the rotary receiver, and empty the carrier strip scrap bin every 1/2 reel of cable ties.

ERROR 6 - Tie in tool

Tie in tool

Help

Unload

Buzzer

Continue

POSSIBLE CAUSE:

This occurs if the cable tie reaches the tool but is prevented from completing the cycle. This

may be due to a large air pressure drop, too large of a bundle, improper feeder hose connections, an obstruction

blocking the cable tie path, a severe bend or twist in the feeder hose, or the tool jaws are opened during the cycle.

CORRECTIVE ACTION:

Remove the cable tie and any obstruction from the jaw area. Resume operation.

electronic components distributor