Page 36

193C-E-PMA01-A04-01

PrintCondition

8-4

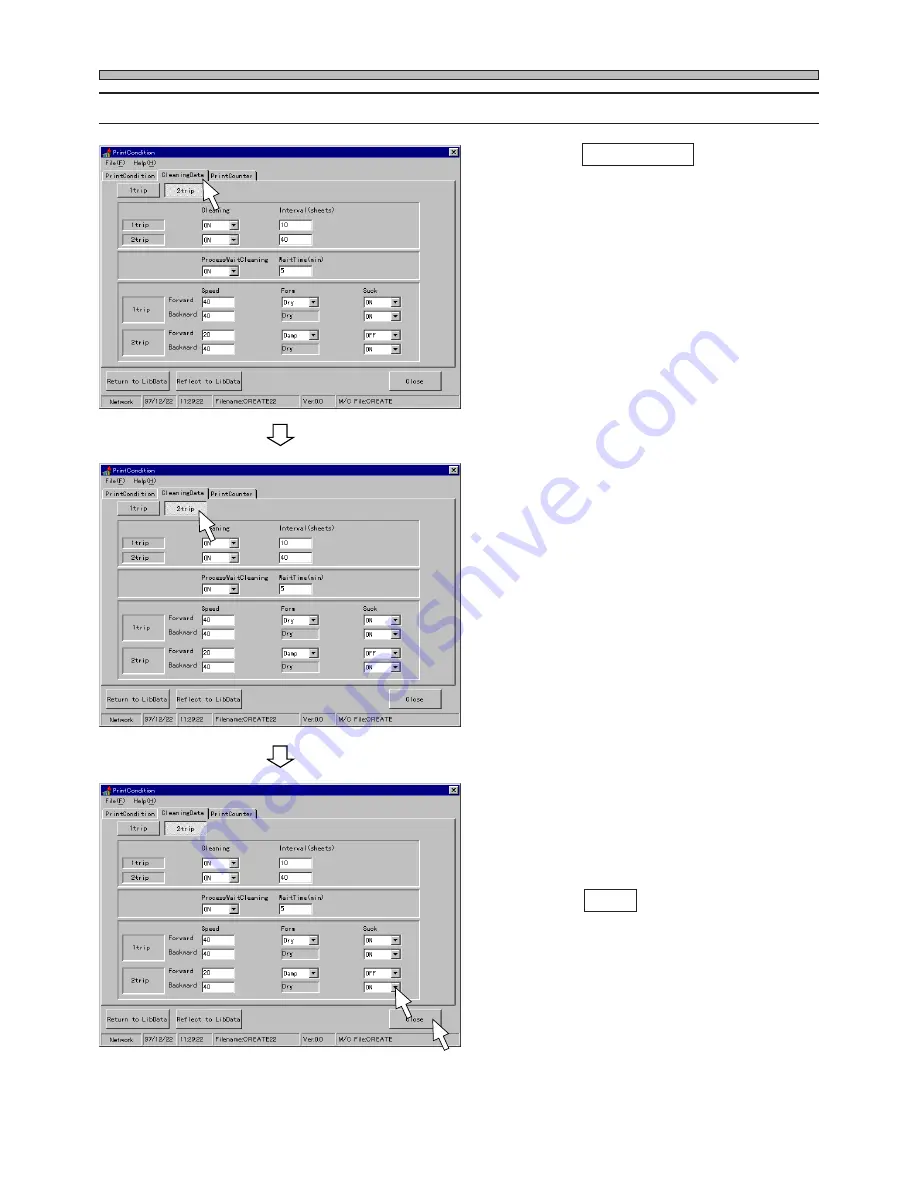

Editing CleaningData

1

. Click on CleaningData .

• [CleaningData] sheet opens.

2

. Choose the motion mode.

3

. Set ProcessWaitCleaning and

WaitTime.

4

. Set Speed, Form and Suck.

5

. Click on Close .

• Main menu is displayed again.

193C-EPt-EdPd-009

193C-EPt-EdPd-009

193C-EPt-EdPd-009

Summary of Contents for SP22P

Page 2: ......

Page 6: ...6 MEMO 193C E PMC00 B02 00...

Page 10: ...MEMO Page 4 193C E PMA00 B03 00...

Page 14: ...Page 4 193C E PMA01 A01 01 MEMO...