29

7.3.1.

COMPASS

7.3.1.1.

General description

7.3.1.2.

Failure diagnosis of Compass

The Compass sensor unit is IC6301 which is located on TOP FPC unit.

Since the IC6301 does not supply as a spare parts, replace as a TOP FPC unit if necessary.

Settings/Condition:

1. Release the initial settings to be forcefully turned off the declination adjustment:

2. Turn on the GPS setting.

3. Press the Display button to display the compass, altimeter, & barometer.

4. Select [Calibrate compass] on the [GPS/Sensor] menu, and then press [MENU/SET].

5. Securely hold the unit vertically, and adjust by turning it in a figure 8 a few times rolling your wrist.

The "Calibration successful" is displayed when the adjustment is successful.

Diagnosis:

1. 1. When both of the red arrow of compass unit and camera unit's one point same direction, the built-in compass unit works

fine.

Summary of Contents for DMC-FT5EA

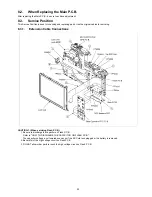

Page 36: ...36 9 Disassembly and Assembly Instructions 9 1 Disassembly Flow Chart 9 2 P C B Location ...

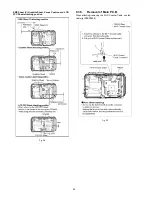

Page 38: ...38 9 3 2 Removal of Rear Aluminum Case Unit Fig D2 9 3 3 Removal of Rear Case Unit Fig D3 ...

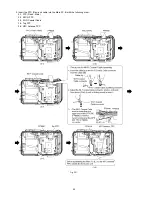

Page 44: ...44 9 3 8 Removal of Top FPC Unit Fig D14 9 3 9 Removal of Speaker Fig D15 ...

Page 46: ...46 9 3 12 Removal of MIC G FPC P C B Fig D18 9 3 13 Removal of LCD Unit Fig D19 ...

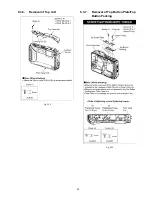

Page 47: ...47 9 3 14 Removal of Rear Operation FPC P C B Fig D20 Fig D21 ...

Page 56: ...56 ...