42

11.3.3 Evacuation of the Equipment

1 Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way

valve.

o

Be sure to connect the end of the charging hose with the push pin to the service port.

2 Connect the center hose of the charging set to a vacuum pump.

3 Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from 0

cmHg (0 MPa) to -76 cmHg (-0.1 MPa). Then evacuate the air approximately ten minutes.

4 Close the Low side valve of the charging set and turn off the vacuum pump. Make sure that the needle in the

gauge does not move after approximately five minutes.

Note: BE SURE TO TAKE THIS PROCEDURE IN ORDER TO AVOID REFRIGERENT GAS LEAKAGE.

5 Disconnect the charging hose from the vacuum pump and from the service port of the 3-way valve.

6 Tighten the service port caps of the 3-way valve at a torque of 18 N•m with a torque wrench.

7 Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “OPEN”

using a hexagonal wrench (4 mm).

8 Mount valve caps onto the 2-way valve and the 3-way valve.

o

Be sure to check for gas leakage.

•

If gauge needle does not move from 0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa), in the step

e

above take the following measure:

-

If the leak stops when the piping connections are tightened further, continue working from step

e

.

-

If the leak does not stop when the connections are retightened, repair location of leak.

-

Do not release refrigerant during piping work for installation and reinstallation.

-

Take care of the liquid refrigerant, it may cause frostbite.

Summary of Contents for CS-A12PKD

Page 12: ...12 4 Location of Controls and Components 4 1 Indoor Unit 4 2 Outdoor Unit 4 3 Remote Control...

Page 13: ...13 5 Dimensions 5 1 Indoor Unit 5 1 1 CS A9PKD CS A12PKD...

Page 14: ...14 5 1 2 CS A18PKD CS A24PKD CS A28PKD...

Page 15: ...15 5 2 Outdoor Unit 5 2 1 CU A9PKD 5 2 2 CU A12PKD...

Page 16: ...16 5 2 3 CU A18PKD...

Page 17: ...17 5 2 4 CU A24PKD CU A28PKD...

Page 18: ...18 6 Refrigeration Cycle Diagram 6 1 CS A9PKD CU A9PKD CS A12PKD CU A12PKD...

Page 19: ...19 6 2 CS A18PKD CU A18PKD CS A24PKD CU A24PKD CS A28PKD CU A28PKD...

Page 20: ...20 7 Block Diagram 7 1 CS A9PKD CU A9PKD...

Page 21: ...21 7 2 CS A12PKD CU A12PKD...

Page 22: ...22 7 3 CS A18PKD CU A18PKD CS A24PKD CU A24PKD...

Page 23: ...23 7 4 CS A28PKD CU A28PKD...

Page 28: ...28 9 Electronic Circuit Diagram 9 1 CS A9PKD CU A9PKD...

Page 29: ...29 9 2 CS A12PKD CU A12PKD...

Page 30: ...30 9 3 CS A18PKD CU A18PKD CS A24PKD CU A24PKD...

Page 31: ...31 9 4 CS A28PKD CU A28PKD...

Page 34: ...34 10 1 4 Comparator Printed Circuit Board 10 1 5 Human Activity Sensor Printed Circuit Board...

Page 40: ...40 11 2 5 Wire Stripping And Connecting Requirement...

Page 48: ...48 12 2 5 Wire Stripping And Connecting Requirement...

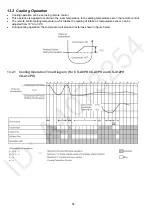

Page 87: ...87 Normal Deice Time Diagram Overload Deice Time Diagram...

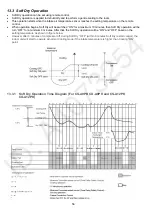

Page 92: ...92 a Normal Deice Time Diagram b Overload Deice Time Diagram...

Page 98: ...98 Figure 3 Figure 4 17 1 1 3 To remove discharge grille Figure 5...

Page 100: ...100 Figure 9 Figure 10...

Page 104: ...104 Figure 20 Figure 21...

Page 105: ...105 18 Technical Data 18 1 Thermostat Characteristics...