37

BRAKE VALVE SERVICE

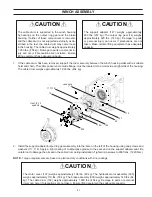

4.

Remove spool plug (Item 4) and carefully remove

spool (5).

5.

Remove the check valve spring retainer (2), spring

(10), and check valve poppet (8). Check spring free

length. Replace spring if less than 1-1/2 inches (38.1

mm) long.

CLEAN AND INSPECT

1. Discard all O-rings and backup rings. Clean all parts

in solvent and blow dry. Inspect polished surfaces of

spool for damage that may cause binding or leakage.

Inspect spool bore in valve housing for damage or

scoring. Inspect check valve seat in valve housing and

check valve poppet. If the spools, bores, or valves are

damaged, the entire valve must be replaced because

these parts are not serviced separately.

2.

Inspect the .020-inch orifice in the pilot orifice (9) to be

certain it is open.

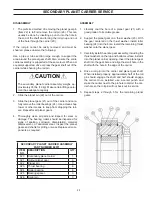

ASSEMBLY

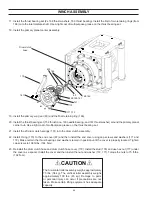

1. Install new O-rings on the plug and spring retainers.

2. Install new O-rings and backup rings on the spool. It

is important that the backup ring is on the correct side

of its O-ring. Take care not to cut the O-ring during

assembly. Let the spool set for 10 minutes before in-

stalling them in their respective bores. This will allow

the O-ring to return to their original size after being

stretched.

3. Lubricate the spool bore and spool O-rings with hy-

draulic oil. Carefully install the spool into the valve

housing. Always install the spool from the plug end as

shown to minimize the possibility of damaging the O-

ring. Install the plug, spool spring and spring retainer.

4. Install the check valve poppet, spring and check valve

spring retainer.

5. Install the solid plug into the drain port.

6.

Install the pilot orifice into the valve housing.

7. The brake valve is complete and ready to be installed

on winch motor.