10

PREVENTIVE MAINTENANCE

GEAR CASE OIL CHANGE

Change the winch gear case oil after the first 100–250

hours of operation, then every 1,000 hours or six months,

whichever occurs first.

Remove the drain plug located at the bottom of the drum

clutch housing. Drain the oil into a suitable container and

recycle or dispose of the used oil in an environmentally re-

sponsible manner. Contact your local government agency

for information concerning proper disposal. Install the plug

securely after draining the oil. To reduce oil drain time, re-

move the filler/vent plug.

Refill the winch to the sight glass with the recommended

oil. Allow 15 minutes for oil to flow through the gear train

and fill the cable drum cavity before checking the oil level.

Oil capacity: approximately 35 qt. (33 L).

VENT PLUG

The vent plug is installed in the oil filler plug located near

the top of the drum clutch housing. Whenever the oil is

changed, remove the vent plug, clean in safety solvent

and reinstall.

NOTE:

Do not replace the vent plug with a solid plug.

The normal expansion of the gear oil during operation will

cause a build-up of pressure in the gear case, which may

lead to seal leakage.

WINCH CABLE (WIRE ROPE)

Inspect the entire length of wire rope and hook in accor-

dance with the rigging manufacturer’s recommendations.

MOUNTING FASTENERS

Check all winch-mounting fasteners and tighten to recom-

mended torque after the first 100–250 hours of operation,

then every 1,000 operating hours or six months, which-

ever occurs first.

A regular program of preventive maintenance for your

CARCO winch will minimize the need for emergency ser-

vicing and promote long product life and trouble-free ser-

vice.

The service intervals suggested in this manual will opti-

mize component service life. The intervals may be gradu-

ally increased or decreased with experience of a particular

lubricant and evaluation of your application.

GEAR CASE OIL

The winch assembly should be visually inspected for leaks

at the beginning of each workday. If you find oil leaks,

check the gear case oil level. If no leaks are detected, the

oil level may be checked once every 250 hours or monthly.

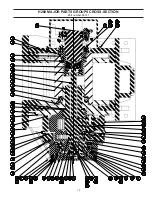

The oil level plug is located at the horizontal centerline on

the drum clutch housing. Position the tractor on a flat, level

surface and remove the plug. The oil should be at the bot-

tom of the level plug hole.

Add oil as required through the oil filler plug located near

the top of the drum clutch housing. Add oil slowly, because

the oil must pass through the gear train and fill the drum

cavity.

Refer to the recommended oil chart for the proper oil for

your application.

TRACTOR HYDRAULIC RESERVOIR LEVEL

Check the tractor hydraulic oil reservoir level at the sight

glass daily or in accordance with the tractor manufactur-

er’s recommendations. Use the type of hydraulic oil rec-

ommended by the tractor manufacturer.

Change the tractor hydraulic oil and filter every 1,000

hours or in accordance with the tractor manufacturer’s

recommendations.

Oil fill

and vent

Oil drain

Oil level

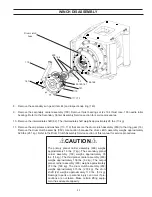

Hot oil may cause injury. Make certain the oil has

cooled to a safe temperature (less than 110ºF or

43ºC) before servicing winch.

!

WARNING

!

DO NOT

operate the winch while the oil is drained.

Serious damage to internal components may result.

CAUTION

!

!