35

ASSEMBLY

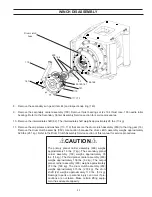

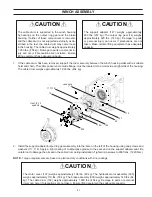

1.

Place the brake housing on a clean, flat surface with

the motor end, or large end, facing up.

2.

Install a brake spacer (Item 305) into the bottom of the

splined bore.

3. Lubricate the friction discs in clean oil, using the same

oil as that intended for the winch gear cavity. Install a

steel brake disk (306) on top of the brake plate spac-

er. Next, install a friction disc (307). Then alternate

steel and friction discs until the last steel disc is placed

on top – nine steel discs and eight friction discs total.

4.

Install the second brake plate spacer (305) on top of

the last steel brake disc. Install the retaining ring (304)

into the groove above the spacer. Make certain the

retaining ring is fully seated into the groove.

5. Turn the brake housing over and rest it on the motor

end. Make certain the brake plates and spacers are

resting flat on the bottom of the bore and are not hung

up or held out of position. Insert the overrunning brake

clutch assembly to more closely align the splines of

the friction discs. Either support the brake clutch as-

sembly in position with a spacer on the table or re-

move it completely.

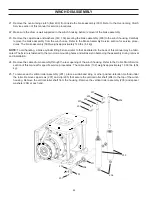

BRAKE ASSEMBLY SERVICE

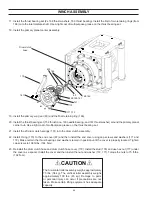

6.

Lubricate the O-rings and backup rings (309, 310, 311,

312) with light grease or petroleum jelly. Install O-rings

and backup rings into the piston grooves. Be sure to

install the backup rings to the outside of the O-rings

toward the ends of the piston. Ensure the concave

surface of the backup rings is against the O-rings.

7.

Install the piston (308) into the brake housing bore. Ap

-

ply light, even pressure to the piston to seat it against

the brake plate spacer.

8.

Insert the spring spacer (314) into piston bore. Insert

16 brake springs (313) into the spring pockets created

by the spacer. Two openings will remain in the spacer.

Ensure that openings are located 180 degrees apart.

9.

Install the spring retainer (315) on top of the brake

springs. Using a press, apply even pressure to the re-

tainer to force it just below the bottom face of the re-

taining ring groove and install the retaining ring (316).

Ensure retaining ring is fully seated in the groove be-

fore removing the pressure from the retainer.

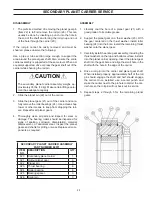

BRAKE ASSEMBLY PRESSURE TEST

Install the long tube fitting into the brake release port of

the brake housing. Connect a hand pump with an accurate

gauge 0–2,000 PSI (0–137.9 bar) and a shut-off valve to

the fitting. Apply 1,000 PSI (68.9 bar) to the brake. Close

the shut-off valve and let the unit stand for 3 to 5 minutes.

If there is any pressure loss, the brake assembly should

be disassembled for inspection of the sealing surfaces

and brake piston seals, and repaired as needed. Perform

this test after any repair to brake assembly.

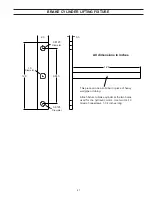

ITEM

NO.

DESCRIPTION

QTY.

301

Brake housing

1

302

Ball, steel

1

303

Pipe plug

1

304

Ring, internal retaining

1

305

Brake plate spacer

2

306

Brake disc

9

307

Friction disc

8

308

Brake piston

1

309

O-ring

1

310

Backup, O-ring

1

311

O-ring

1

312

Backup ring

1

313

Spring

16

314

Spring spacer

1

315

Spring retainer

1

316

Retaining ring

1

306

305

304

303

301

308

314

313

312 311

310

309

315

316

302

307

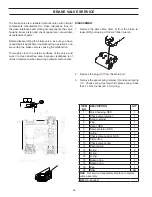

The brake housing weighs approximately 110 lbs. (50

kg). Ensure lifting equipment has adequate capacity.

CAUTION

!

!