21

WINCH REMOVAL AND INSTALLATION

Cleanliness around all hydraulic components is of utmost

importance. Before starting any repair procedures, thor-

oughly clean the parts to be removed, as well as adjacent

areas of the tractor, to avoid entry of dirt into the winch and

winch control system. Do not leave any ports or access

openings exposed to the weather. Seal or cap the open-

ings to prevent entry of dust, moisture or other foreign ma-

terial. Cap or plug all exposed hydraulic ports and fittings.

During disassembly, be careful not to damage seals and

O-rings to be reused. Replace any damaged or defective

parts. Certain O-rings and seals specified in the replace

-

ment instructions must not be reused. In general, seals and

O-rings that work under operating hydraulic pressures, or

that require extensive disassembly to replace, should be

replaced with new parts at the time of reassembly.

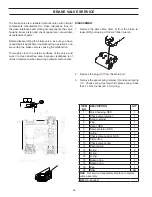

WINCH REMOVAL

Place the tractor and winch in a level position and drain

the oil from the winch into a suitable container. Install the

drain plug securely after oil has drained completely.

NOTE:

Due to the configuration of the cable drum, a small

amount of oil will remain within the drum cavity.

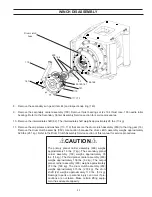

Remove the winch motor hoses from the motor and brake

valve. Remove the motor shift hose from the motor X port.

Remove the motor drain hose from the motor. Remove the

drum clutch hose from the elbow on the right of the winch

case.

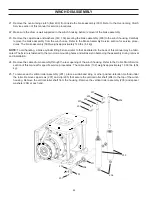

Support the winch with a suitable hoist or platform and

remove the nuts and bolts securing the winch to the tractor

adapters, and move the winch away from the tractor.

WINCH INSTALLATION

For first-time installation, contact PACCAR Winch Engi

-

neering for your specific tractor. A detailed scope of work

is put forth in this document and describes all tractor modi-

fications and adaptation.

Remove dirt, paint and rust from the mounting surfaces of

the winch and tractor adapters.

Align the winch-mounting holes with the adapter mounting

holes, and install and tighten all fasteners to the recom-

mended torque.

Fill the hydraulic motor case, through the motor case drain

port, with tractor hydraulic oil. Attach the winch control

hoses to the motor, as defined in the parts and installation

manual.

Fill the winch to the proper level with the recommended oil.

Allow five minutes for the oil to flow through the gear train

and fill the drum cavity before checking the oil level.

Start the tractor engine and operate the engine at low

RPM. Alternately, place the winch control in the reel-in,

then the reel-out position until the winch motor hydraulic

circuit is filled with oil and the winch operates smoothly.

Check the tractor hydraulic oil reservoir and fill to the prop

-

er level as required.

Winch weighs approximately 7,040 lbs. (3,193 kg)

without oil, cable and tractor adapters. Make cer-

tain the lifting equipment has adequate capacity. At-

tempting to lift the winch with inadequate equipment

may result in personal injury and product or property

damage.

!

WARNING

!

Hot oil may cause injury. Make certain the oil has

cooled to a safe temperature (less than 110ºF or

43ºC) before servicing winch.

!

WARNING

!

Before servicing, make sure any trapped oil pressure

in the tractor hydraulic system has been relieved.

Personal injury may result from a sudden release of

oil pressure. Relieve trapped pressure by cycling the

blade and winch control levers several times after

turning off the tractor engine. Relieve any trapped oil

pressure in the hydraulic reservoir by opening the fill

cap. Be sure to activate the winch or tractor hydrau-

lic system lock-out toggle switch(es) or as directed in

the tractor service manual.

!

WARNING

!

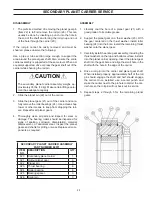

Failure to fill the motor case with hydraulic oil before

operating the winch may result in serious damage to

the motor.

CAUTION

!

!