11

OIL SAMPLING AND ANALYSIS

Proper oil sampling and analysis of the sample, is a vital

part of a comprehensive preventive maintenance program.

Information obtained from the oil analysis is best utilized in

conjunction with a regular program of preventive mainte-

nance. The early warning of abnormal wear provided by

an analysis program allows the user to substitute preven-

tive maintenance for a far more costly and dangerous fail-

ure that may lead to loss of load control that could result in

property damage, personal injury or death. Early detection

of accelerated component wear allows the scheduling of

corrective maintenance and can reduce in-operation fail-

ures and costly down time.

Taking a Valid Oil Sample

Since the GH30B-FF hoist has an oil seal which separates

the free-fall end oil from the motor end oil, a sample from

each end must be analyzed at each maintenance interval.

Prepare the hoist by cleaning the drain area and drain ex-

tension tube in order to obtain an uncontaminated sample.

Operate the hoist in both directions for one to two minutes

and then take the oil sample from the drain port as soon as

possible. Do not take the sample from the fi rst oil out of the

drain port. Take a sample from the mid-stream fl ow of the

oil to obtain an accurate representation of the oil condition.

After taking an oil sample, refi ll hoist with recommended

lubricant.

Analysis

General Guide Lines

(After approximately 250 hours of operation)

Note:

The fi rst oil change usually contains more “wear

metals”. Following the initial break-in period, the wear

metal levels should stabilize at a lower number.

Iron Contaminates

100 to 400

ppm Normal

400 to 700

ppm Caution – Abnormal Sample (monitor

more frequently), tear-down inspection

may be required.

701 ppm & up

Unacceptable – Abnormal Sample (tear

down inspection required)

In all contaminate monitoring, equally important as the

level of contamination, is the change in the amount of con-

tamination compared to previous samples.

Moisture contamination will lead to the formation of acids

that damage all internal components. Silica found in the oil

typically indicates “dirt” and contaminated lubricant supply

or poor maintenance practices.

Hot oil may cause personal injury and/or burns to un-

protected skin. Make certain the oil has cooled to a safe

temperature (less than 110°F or 43°C) before taking an

oil sample, changing oil or servicing the hoist.

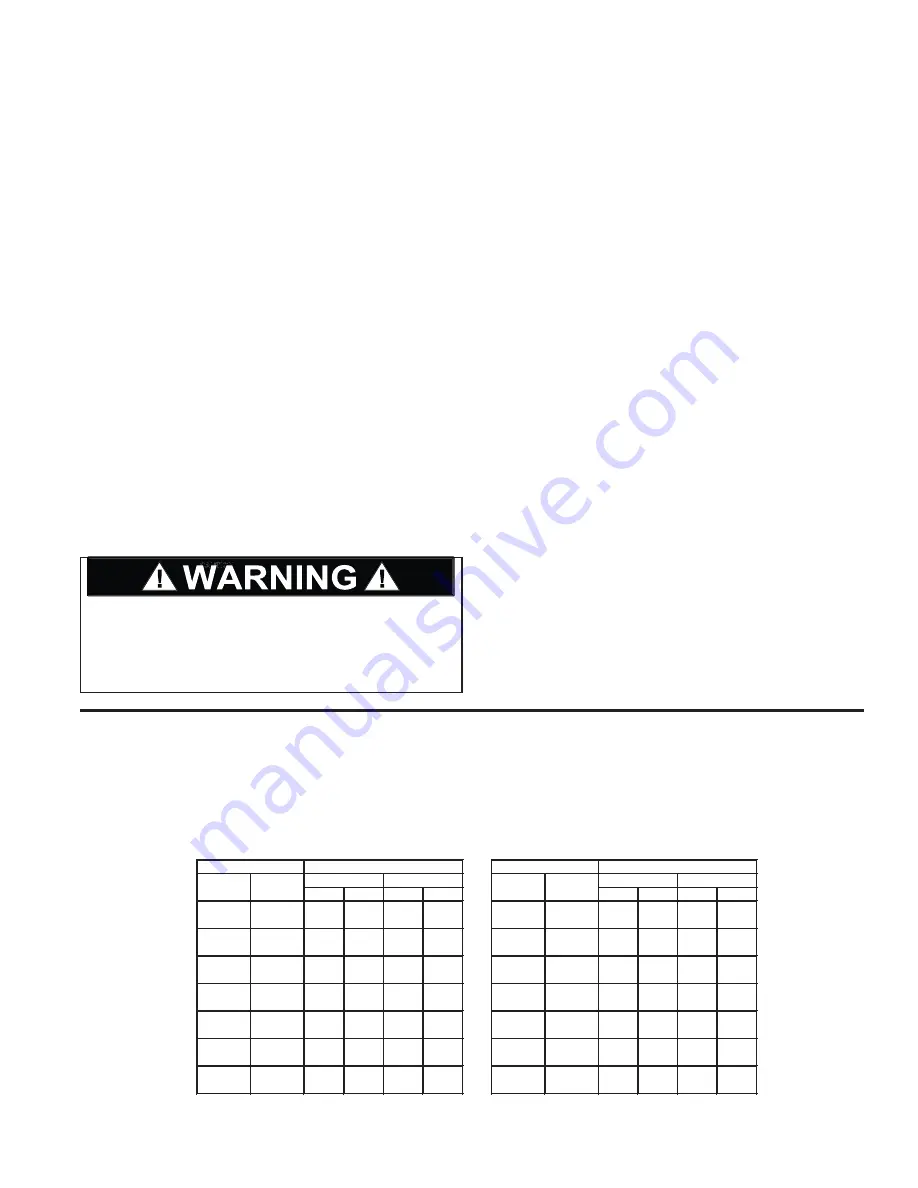

RECOMMENDED BOLT TORQUE

The general purpose torque shown in the chart applies to SAE Grade 5 & Grade 8 bolts, studs and standard steel full, thick and

high nuts.

Higher or lower torques for special applications will be specifi ed such as the use of spanner nuts, nuts on shaft ends, jam nuts and

where distortion of parts or gaskets is critical.

Lubricated torque values based on use of SAE 30 engine oil applied to threads and face of bolt or nut.

Dry

Lubed

Dry

Lubed

Dry

Lubed

Dry

Lubed

Torque (LB-FT)

Grade 5

Grade 8

1/4

20

28

5/16

3/8

18

24

16

24

7/16

1/2

9/16

5/8

8

6

12

9

17

13

24

18

45

35

70

50

23

31

50

35

80

110

80

150

110

110

55

75

150

115

210

160

14

20

13

20

12

18

11

18

265

200

Torque (LB-FT)

Grade 5

Grade 8

380

280

7/8

9

14

420

325

600

450

3/4

10

16

680

1 1/8

7

12

790

590

1290

970

1

8

14

640

7

12

1120

835

910

485

1460

1820

1360

1 3/8

6

12

1460

1095

2385

1790

1 1/4

3160

2370

RECOMMENDED FASTENER TORQUE

Bolt Dia.

Inches

Thds Per

Inch

Bolt Dia.

Inches

Thds Per

Inch

1 1/2

6

12

1940

LB-FT X 1.3558 = N-M X 0.7376 = LB-FT

LB-FT X 0.1383 = Kg-m X 7.233 = LB-FT