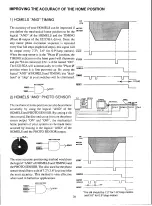

IMPROVING THE ACCURACY OF THE HOME POSITION

PLC

-

STARTUI21SGA

2-PHASE

STEP

MOTOR

TABLE

CCW

C

C

W

DI

SC

WITIL SLIT

RESET

T M °

IIIHOMELS OS-STOP DCWLS

S-STOP

P„OT0SELISORlirWLS

OUTPuT

'VW

1) HOMELS "AND" TIMING

The accuracy of your HOMELS can be improved if

you define the mechanical home position to be the

logical "AND" of the HOMELS and the TIMING

(Phase 0) output of the UI215GA driver. Since the

step motor phase excitation sequence is repeated

every four full steps (eight half steps), this signal will

be output every 7.2°( 3.6° for 0.9°/step motors).

When the step motor is in the "Phase CI" position, the

TIMING indicator on the front panel will illuminate

and pin '34 on connector CN 1 will be turned "ON".

The UI215GA will automatically be in the "Phase 0"

position when it is first powered-up. By using the

logical "AND" of HOMELS and TIMING, any "dead-

band" or "slop" in your switches will be eliminated.

AND

FUNCTI

ON

2) HOMELS "AND" PHOTO SENSOR

The mechanical home position can also be set more

accurately by using the logical "AND" o f the

HOMELS and PHOTO SENSOR. By cutting a slit

into a round, flat disc and using it to turn the photo

sensor output "ON" and "OFF", the mechanical

home position of your system can be made more

accurate by making it the logical "AND" of the

HOMELS and the PHOTO SENSOR output.

SLIT

AND FUNCTION

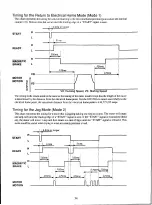

RESET

The most accurate positioning method would use

the logical "AND" of HOMELS and TIMING and

the PHOTO SENSOR. The disc used for the photo

sensor should have a slit of 7.2° (3.6°) cut into it for

the most accuracy. This method is very effective

when used in ballscrew applications.

AND FUNCTION

CW

CCW

MOTOR

MOTION

START

S-STOP

HOMELS

TIMING

RESET

Li

1.0 7 213 61

20

CW

CCW

MOTOR

MOTION

START

S-STOP

HOMELS

PHOTO

SENSOR

RESET

I..

360'

1

*The slit should be 7.2° for 1.8°/step motors

and 3.6° for 0.9°/step motors.