User Manual – eSX

OptiPro Systems, LLC.

Page 52 of 111

Last Modified: 8/27/2014

Cut and Feed Parameters

Description

Tool Velocity

(Calculated) Determined by programmed RPM and tool diameter.

Feed Rate

Rate of tool-to-lens feed after Safety Height is reached (Feed will be

“Rapid” prior to reaching the Safety Height).

Dwell

Time to dwell during cut at Finished CT before retracting.

Retract Height

(Optional) Distance to travel away at commanded Feed Rate before

“Rapid” retract.

Retract Feed Rate

The rate at which the tool will retract off of the part before rapid retract.

Coolant Through

(Optional) If active, will activate coolant center-feed through the spindle.

Vacuum Monitoring

(Optional) If active, will monitor for vacuum loss during a processing cycle.

SPC Monitoring

(Optional) Will broadcast time/date stamped part count information across

a network.

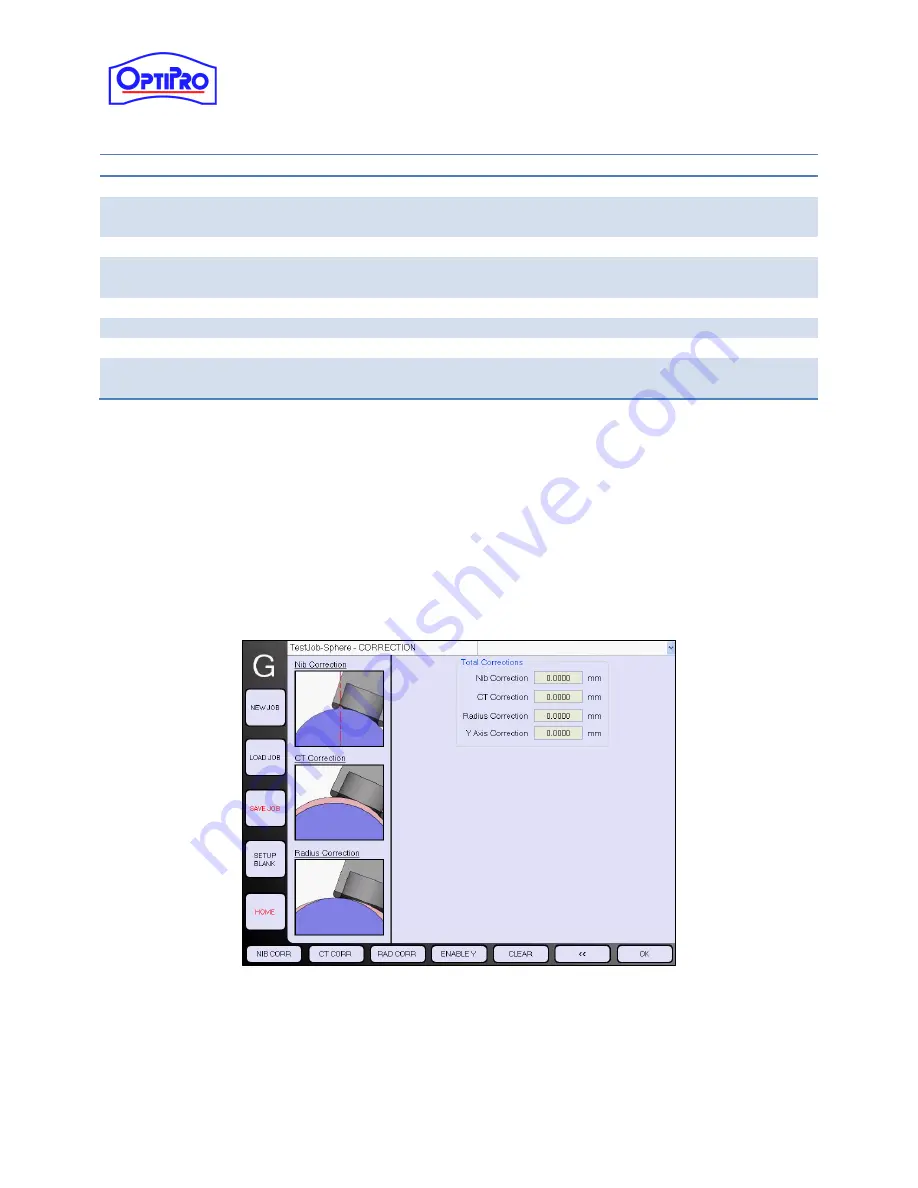

9.

Advance to the Spherical Corrections screen by tapping [>>].

10.

The main Spherical Process Corrections screen will display any active correction values.

a.

To proceed without adding correction parameters tap [OK] to return to the main job

screen, then tap [SAVE JOB] to save the new or modified process to the job file.

b.

To add correction parameters tap the appropriate image or button in the function bar.

Note that the images will reflect if the current process is convex or concave.

c.

To clear any active corrections tap [CLEAR], then select the correction type to clear and

tap [OKAY] to return to the main corrections screen.

Figure 7-19: Spherical Process

–

Main Corrections Screen