Version 1.0.5 - 2020-12-09

28

Translation of original instructions

TX4414

GB

T

X

4414

_GB

_3.

fm

3.6.1

Anchor-free assembly

This must be done by laying down a strong base on each support of the levelling points,

between the foundation and the machine foot.

3.6.2

Installation with levelling- damping elements

Optional levelling- damping elements

Attaching of 6 pieces SE2 levelling- damping elements on levelling points between the founda-

tion and machine foot.

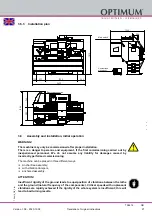

Levelling- damping element dimension

3.6.3

Installation with vibration dampers

Optional vibration dampers

Attaching of 6 pieces SE85 vibration dampers on levelling points between the foundation and

machine stand.

In order to obtain optimum anti-slip protection, the subfloor must be free of oil and grease

before the machine or system is installed.

CAUTION!

The max. load per element refers to the sum of static plus dynamic forces. The machine

must not be moved after the machine has been lowered!

Lift the machine with suitable lifting gear so that the SE85 elements can be pushed underneath.

Insert the levelling screw (1) without the lower large levelling nut (2) from above into the through

hole of the machine foot. Then screw the levelling nut (2) onto the levelling screw from below.

Adjust the levelling screw with the levelling nut until it stands up in the spherical holder of the

vibration damper (3). The screw must be vertical in the through hole. Carry out these preparati-

ons at all support points, and now carefully lower the machine further and level it via the level-

ling nut by holding it against the upper hexagon or lower two-edge of the levelling screw. After

levelling, screw the upper lock nut (4) with washer onto the levelling screw and tighten.

A

B [mm]

C [mm]

D [mm]

E [mm]

SE1

M12

70

10

32

120

SE2

M16

90

12

35

160

SE3

M20

130

12

40

185

Jackscrew

Counternut

A

B

C

D

E