6-2

Section

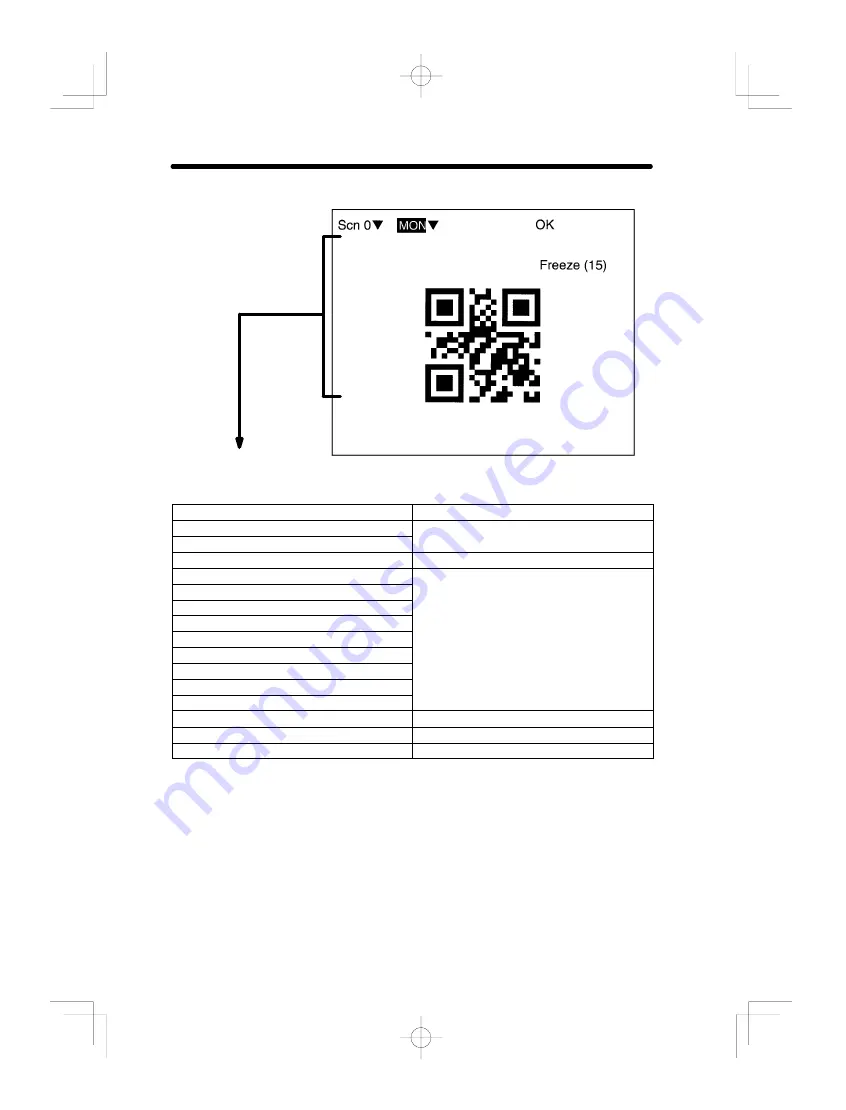

MON (Monitor) Mode

154

When

Detail Data is ON:

Detailed data of reading codes are displayed.

QR Code (Normal or Pattern Mode)

Number of FP

Number of finder patterns detected

Retry; Gray Edge Value (Normal)

Setting conditions

Retry; Correlation (Pattern)

Setting conditions

Thresh

Threshold value for black and white discrimination

Format Inf. Count

Information, such as the version of the model read from

th

d

d th

ti

l

l

Format Error

Information, such as the version of the model read from

the code and the error correction level.

Mask Pattern

Error Correctable Level

Model

Temporary Version

Version

X, Y Version

Reed Solomon Error

Length A-B

Length between finder patterns (pixel units)

Pixel/Cell

Number of pixels per cell

Angle

Code Angle

205ms

Number of FP=4 (1)

Retry=0, GrayEdgeValue=32

Thresh=147

Format, Inf. Count=1

Format, Error=0

Mask Pattern=0

Error Correctable Level=L (30%)

Model=1

Temporary Version=1

Version=1

X, Y Version=1, 1

Reed Solomon Error=0

Length A–B=137.0

Pixel/Cell=9.8

Angle=90