400433D-EN

1 - 1

Chapter 1

Safety First

This chapter describes the safety labels appearing on the OMAX JetMachining Centers and identifies where

each are located. These labels provide information essential for safe equipment operation. This chapter also

emphasizes important safety precautions that must be observed while operating or servicing and maintaining

this equipment, and identifies the safety devices built into this equipment.

Note:

OMAX recommends the implementation of practices and procedures to shut down equipment, isolate it

from its energy source(s), and prevent the release of potentially hazardous energy while maintenance and

servicing activities are being performed.

Safety Labels

Safety

Label

Description

Wear Gloves

Since bacteria in the tank water can build up, even a seemingly minor break in the skin can introduce

harmful bacteria into a wound. Always wear protective gloves if you have cuts or open wounds on your

hands. When setting up material for cutting, always wear gloves that provide protection against sharp

metal edges.

Electrical Hazard

Indicates the presence of life-threatening voltages. Never access areas labeled as such without first

taking appropriate safety precautions: locking out power, verifying no voltage present on circuits prior

to maintenance activities, etc.

Lock Out Power

Never open or do maintenance on the OMAX equipment with the main AC disconnect ON or unlocked,

or while the pump unit is operating. Always follow standard lockout/tag-out procedures.

Don’t apply power to the equipment while maintenance work is in progress. Always lock the main

power to the OMAX pump off at its source.

Eye Protection

Always wear approved safety goggles whenever cutting.

Regular glasses are not sufficient eye

protection!

Ear Protection

Always wear hearing protection while in the vicinity of the OMAX. When cutting in air, noise levels can

exceed 120 dB.

Flying Debris/Loud Noise

Eye and ear protection are always required during operation.

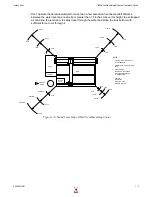

Emergency Stop Switch

Pushing the emergency stop switch in immediately shuts down water pump and abrasivejet operation.

The emergency stop switch should be used only for real emergencies. When pressed, the OMAX loses

important machine position. The equipment cannot be restarted until the emergency stop switch is

reset.

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...